Tuam Tshoj Prefabricated Steel Structure rau Rhiav Chaw Ua Haujlwm Tsev

Cov hlau muaj zog, zoo plasticity, cov khoom siv sib xws, kev ntseeg siab ntawm cov qauv, tsim nyog rau kev tiv taus kev cuam tshuam thiab cov khoom thauj dynamic, thiab muaj kev tiv thaiv av qeeg zoo. Cov qauv sab hauv ntawm cov hlau yog sib xws thiab ze rau isotropic homogeneous lub cev. Kev ua haujlwm tiag tiag ntawm cov qauv hlau yog sib xws nrog kev xam lej. Yog li ntawd, cov qauv hlau muaj kev ntseeg siab siab.

Cov khoom siv muaj zog thiab sib dua. Hlau muaj zog thiab modulus siab ntawm elasticity. Nws qhov ceev rau cov zis zog piv yog qis dua piv rau cov pob zeb thiab ntoo. Yog li ntawd, nyob rau hauv tib qho kev ntxhov siab, lubqauv hlauCov tswv cuab muaj cov ntu me me thiab tsis hnyav. Lub tsev mb lightweight steel concrete ntsuab yooj yim thauj thiab teeb tsa, thiab tsim nyog rau cov qhov loj, qhov siab siab, thiab cov khoom hnyav. qauv.

* Xa email mus rau[email tiv thaiv]kom tau txais ib daim ntawv hais txog koj cov haujlwm

TXHEEJ TXHEEM TXOG KEV TSIM KHOOM

| Lub npe khoom: | Tsev Hlau Qauv Hlau |

| Khoom siv: | Q235B, Q345B |

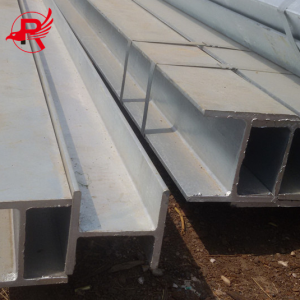

| Lub thav duab tseem ceeb: | H-puab hlau beam |

| Purlin: | C, Z - cov hlau purlin zoo |

| Ru tsev thiab phab ntsa: | 1. daim ntawv hlau corrugated; 2. pob zeb wool sandwich panels; 3.EPS sandwich panels; 4. cov iav ntaub plaub sandwich panels |

| Qhov Rooj: | 1. Rooj vag dov 2. Qhov rooj zawv zawg |

| Qhov Rai: | PVC hlau los yog txhuas hlau |

| Lub qhov dej ntws hauv qab: | Cov yeeb nkab pvc puag ncig |

| Daim Ntawv Thov: | Txhua yam kev cob qhia kev lag luam, tsev rau khoom, tsev siab |

QHOV ZOO

prefabricated hlau qauvmuaj qhov zoo ntawm qhov hnyav sib dua, kev ntseeg siab ntawm cov qauv, qib siab ntawm kev siv tshuab ntawm kev tsim khoom thiab kev teeb tsa, kev ua tau zoo sealing, cua sov thiab hluav taws tsis kam, carbon tsawg, txuag hluav taws xob, ntsuab thiab kev tiv thaiv ib puag ncig.

Cov qauv hlau yog ib qho qauv uas muaj cov khoom siv hlau thiab yog ib hom qauv tsev tseem ceeb. Cov qauv no feem ntau yog ua los ntawm cov hlau beams, cov hlau kem, cov hlau trusses thiab lwm yam khoom ua los ntawm cov hlau zoo li tus thiab cov hlau phaj, thiab siv cov txheej txheem tshem tawm xeb thiab tiv thaiv xeb xws li silanization, ntshiab manganese phosphating, ntxuav thiab ziab, thiab galvanizing. Txhua yam khoom lossis cov khoom feem ntau txuas nrog welds, bolts lossis rivets. Vim nws qhov hnyav sib dua thiab yooj yim tsim kho, nws yog siv dav hauv cov chaw tsim khoom loj, chaw ua si, super high-rises thiab lwm yam teb. Cov qauv hlau yooj yim rau xeb. Feem ntau, cov qauv hlau yuav tsum tau derusted, galvanized lossis pleev xim, thiab yuav tsum tau saib xyuas tsis tu ncua.

Lub zog siab thiab lub teeb yuag. Piv nrog cov pob zeb ua vaj tse thiab ntoo, qhov ceev thiab lub zog tso zis qis dua. Yog li ntawd, nyob rau hauv tib qho kev ntxhov siab, cov tswv cuab ntawm cov qauv hlau muaj cov ntu me me, lub teeb yuag, yooj yim thauj mus los thiab teeb tsa, thiab tsim nyog rau cov qauv loj, siab, hnyav. Cov cuab yeej hlau muaj cov tawv zoo thiab plasticity, cov ntaub ntawv sib xws, kev ntseeg siab ntawm cov qauv, tsim nyog rau kev tiv taus kev cuam tshuam thiab cov khoom thauj dynamic, thiab muaj kev tiv thaiv av qeeg zoo. Cov qauv sab hauv ntawm cov hlau yog sib xws thiab ze rau isotropic homogeneous lub cev. Kev ua haujlwm ntawm cov qauv hlau ua raws li kev xam suav, yog li nws muaj kev nyab xeeb thiab kev ntseeg siab siab.

Lub zog siab thiab lub teeb yuag. Piv nrog cov pob zeb ua vaj tse thiab ntoo, qhov ceev thiab lub zog tso zis qis dua. Yog li ntawd, nyob rau hauv tib qho kev ntxhov siab, cov tswv cuab ntawm cov qauv hlau muaj cov ntu me me, lub teeb yuag, yooj yim thauj mus los thiab teeb tsa, thiab tsim nyog rau cov qauv loj, siab, hnyav. 2. Cov cuab yeej hlau muaj cov khoom siv zoo thiab plasticity, cov ntaub ntawv sib xws, kev ntseeg siab ntawm cov qauv, tsim nyog rau kev tiv taus kev cuam tshuam thiab cov khoom thauj dynamic, thiab muaj kev tiv thaiv av qeeg zoo. Cov qauv sab hauv ntawm cov hlau yog sib xws thiab ze rau isotropic homogeneous lub cev. Kev ua haujlwm ntawm cov qauv hlau ua raws li kev xam suav, yog li nws muaj kev nyab xeeb thiab kev ntseeg siab siab.

TSO NYIAJ

Hauv kev tsim kho cov haujlwm tsim kho, kev siv covCov ntaub ntawv tsev hlaukev tsim kho vaj tse tsis yog tsuas yog tso cai rau qhov project tsim kho kom muaj qhov chaw loj dua xwb, tab sis kuj muaj qhov zoo ntawm kev teeb tsa yooj yim thiab tus nqi qis, uas ua rau nws daim ntawv thov hauv cov haujlwm tsim kho kom dav dua. Nrog rau kev txhim kho ntxiv ntawm kuv lub teb chaws txoj kev loj hlob hauv nroog, tus lej ntawm cov tsev siab yuav nce ntxiv, uas tso cov kev xav tau siab dua rau kev tsim cov haujlwm tsim kho hlau.

Nyob rau hauv xyoo tas los no,Tsim Qauv Hlautau siv ntau dua thiab ntau dua hauv cov haujlwm tsim kho, thiab tau ua tiav cov txiaj ntsig zoo heev. Txawm li cas los xij, hauv cov txheej txheem thov tiag tiag, kuj muaj teeb meem nrog kev ruaj khov tsis txaus ntawm cov tsev qauv hlau vim tsis tsim cov haujlwm qauv hlau tsis zoo, uas cuam tshuam loj heev rau kev nyab xeeb ntawm cov neeg siv lub neej thiab khoom vaj khoom tsev. Yuav kom ntseeg tau tias kev tsim kho cov haujlwm qauv hlau muaj qhov zoo dua, nws yog qhov tsim nyog los ua raws li cov lus qhia thiab cov qauv sib xws thaum tsim cov haujlwm qauv hlau, thiab ua cov haujlwm tsim qauv tseem ceeb, kom muab cov neeg siv nrog ntau lub tsev qauv hlau muaj kev nyab xeeb thiab txhim khu kev qha.

KEV TSHAWB XYUAS KHOOM

1. Tshawb nrhiav qhov loj thiab qhov tiaj tiaj ntawm cov khoom. Txhua qhov ntev ntsuas ntawm 3 qhov ntawm cov khoom, thiab tus nqi nruab nrab ntawm 3 qhov chaw yog coj los ua tus nqi sawv cev ntawm qhov ntev. Qhov sib txawv ntawm cov khoom hlau yuav tsum tau xam raws li qhov ntev teev tseg hauv cov duab kos; tus nqi tso cai ntawm qhov sib txawv yuav tsum ua raws li cov kev cai ntawm nws cov qauv khoom. Kev hloov pauv ntawm cov nqaj hlau thiab cov tswv cuab truss suav nrog kev hloov pauv ntsug hauv lub dav hlau thiab kev hloov pauv sab nraud ntawm lub dav hlau, yog li qhov ncaj hauv ob qho kev taw qhia yuav tsum tau kuaj pom. Kev hloov pauv ntawm kem feem ntau suav nrog kev tilting thiab deflection ntawm lub cev kem.

Thaum kuaj xyuas, yuav tsum kuaj xyuas ua ntej. Yog tias muaj qhov tsis zoo lossis tsis ntseeg, yuav tsum siv hlau lossis hlau nyias nyias los ntswj rau ntawm cov fulcrums ntawm cov beams thiab trusses, thiab tom qab ntawd yuav tsum ntsuas qhov sag thiab qhov sib txawv ntawm txhua qhov; yuav tsum ntsuas qhov inclination ntawm kem nrog theodolite lossis lead. Kev ntsuas ntsug. Kev hloov pauv ntawm kem yuav tsum ntsuas los ntawm kev ncab hlau lossis hlau nyias nyias ntawm cov fulcrum ntawm tus tswv cuab.

2. Kev kuaj pom ntawm cov hlau xeb

Cov qauv hlau feem ntau yuav xeb nyob rau hauv cov chaw uas muaj dej noo, muaj dej thiab muaj kua qaub-alkali-ntsev corrosive. Xeb ua rau cov hlau tsis muaj zog thiab lub peev xwm bearing txo qis. Qhov degree ntawm xeb ntawm hlau tuaj yeem pom los ntawm kev hloov pauv ntawm nws qhov tuab ntawm ntu. Cov cuab yeej siv los ntes cov tuab ntawm hlau (xeb yuav tsum tau tshem tawm ua ntej) suav nrog ultrasonic thickness gauges (suab ceev teeb tsa, tus neeg sawv cev txuas) thiab vernier calipers. Lub ultrasonic thickness gauge siv txoj kev pulse reflection wave. Thaum ib lub ultrasonic wave kis los ntawm ib qho nruab nrab mus rau lwm qhov, nws yuav raug cuam tshuam ntawm qhov interface. Lub thickness gauge tuaj yeem ntsuas lub sijhawm txij li thaum lub probe tso tawm lub ultrasonic wave mus rau thaum nws tau txais lub interface reflection echo. Qhov ceev ntawm propagation ntawm ultrasonic waves hauv ntau yam khoom siv hlau paub, lossis txiav txim siab los ntawm kev ntsuas tiag tiag. Qhov tuab ntawm hlau yog xam los ntawm qhov ceev ntawm nthwv dej thiab lub sijhawm propagation. Rau cov digital ultrasonic thickness gauges, tus nqi tuab yuav raug tso tawm ncaj qha rau ntawm qhov screen.

3. Kev tshawb pom qhov tsis zoo ntawm cov khoom sib nqus

Lub hauv paus ntsiab lus ntawm kev tshuaj xyuas cov khoom sib nqus: Thaum muaj qhov tsis zoo hauv cov qauv hlau, xws li cov kab nrib pleb, cov khoom sib xyaw, cov qhov hws thiab lwm yam khoom tsis yog ferromagnetic, qhov tsis kam ntawm cov hlau nplaum loj heev thiab qhov permeability ntawm cov hlau nplaum qis, uas yuav ua rau kev faib tawm ntawm cov kab sib nqus ntawm lub zog hloov pauv. Cov kab sib nqus ntawm qhov tsis zoo tsis tuaj yeem hla dhau thiab yuav khoov rau qee qhov. Thaum cov qhov tsis zoo nyob rau ntawm lossis ze rau ntawm qhov chaw ntawm cov qauv hlau, lawv yuav xau los ntawm qhov chaw ntawm cov qauv hlau mus rau hauv huab cua los tsim cov teb sib nqus xau zoo.

Qhov muaj zog ntawm lub zog ntawm lub zog magnetizing thiab qhov cuam tshuam ntawm cov qhov tsis zoo ntawm qhov ntsug ntawm lub zog magnetizing. Cov hmoov sib nqus tuaj yeem siv los tso saib lossis ntsuas lub zog magnetic xau, yog li ntawd los tshuaj xyuas thiab txiav txim siab qhov muaj, qhov chaw thiab qhov loj ntawm cov qhov tsis zoo.

PROJECT

Peb lilub tuam txhab tsim qauv hlaufeem ntau xa cov khoom siv hlau mus rau Asmeskas thiab cov tebchaws Es Xias Qab Teb. Peb tau koom nrog ib qho ntawm cov haujlwm hauv Asmeskas nrog thaj tsam tag nrho kwv yees li 543,000 square meters thiab siv tag nrho kwv yees li 20,000 tons hlau. Tom qab ua tiav qhov project, nws yuav dhau los ua ib lub tsev hlau uas muaj kev koom ua ke ntawm kev tsim khoom, kev nyob, chaw ua haujlwm, kev kawm thiab kev ncig tebchaws.

DAIM NTAWV THOV

Kev lag luam petrochemical: Cov qauv hlau siv dav hauv kev lag luam petrochemical, suav nrog ntau yam khoom siv tshuaj lom neeg, cov kav dej, cov thoob dej cia khoom, cov reactors, thiab lwm yam. Cov qauv hlau muaj qhov zoo ntawm kev tiv thaiv corrosion zoo, lub zog siab, thiab kev tiv thaiv kub siab, thiab tuaj yeem ua tau raws li qhov xav tau ntawm kev lag luam petrochemical rau kev ruaj khov thiab kev nyab xeeb ntawm cov khoom siv.

Kev tsim tsheb: Cov qauv hlau tau siv dav hauv kev tsim tsheb, suav nrog tsheb, tsheb ciav hlau, tsheb ciav hlau hauv av, tsheb ciav hlau me thiab lwm yam kev thauj mus los. Cov qauv hlau muaj qhov zoo ntawm qhov hnyav sib dua, lub zog siab, yooj yim ua, thiab ruaj khov, thiab tuaj yeem ua tau raws li qhov xav tau ntawm kev nyab xeeb tsheb thiab kev lag luam hauv kev tsim tsheb.

Kev Tsim Nkoj: Cov qauv hlau tau siv dav hauv kev tsim nkoj, suav nrog ntau lub nkoj pej xeem thiab cov nkoj tub rog. Cov qauv hlau muaj qhov zoo ntawm qhov hnyav sib dua, lub zog siab, yooj yim ua, thiab tiv taus corrosion zoo, thiab tuaj yeem ua tau raws li qhov yuav tsum tau ua rau kev nyab xeeb thiab kev ruaj khov ntawm nkoj hauv kev tsim nkoj.

Hauv ntej, cov qauv hlau yog ib hom qauv siv dav dav, tsim nyog rau cov haujlwm hauv ntau qhov chaw, zoo rau ib puag ncig, txuag hluav taws xob, thiab siv tau dua, thiab yog ib qho ntawm cov lus qhia tseem ceeb rau kev txhim kho kev tsim kho yav tom ntej. Yog tias koj xav paub ntau ntxiv txog cov lag luam siv tau ntawm cov qauv hlau, thov ua raws li peb thiab tawm lus!

NTIM THIAB XA KHOOM

Cov qauv hlau tiv taus cua sov tab sis tsis tiv taus hluav taws. Thaum qhov kub qis dua 150 ° C, cov yam ntxwv ntawm hlau hloov me ntsis. Yog li ntawd, cov qauv hlau tsim nyog rau cov chaw ua haujlwm kub siab, tab sis thaum qhov chaw ntawm cov qauv raug hluav taws xob thermal ntawm kwv yees li 150 ° C, nws yuav tsum tau tiv thaiv los ntawm cov vaj huam sib luag rwb thaiv tsev kub. Thaum qhov kub nyob nruab nrab ntawm 300 ° C thiab 400 ° C, lub zog thiab elastic modulus ntawm hlau txo qis heev.

LUB TUAM TXHAB LUB ZOG

Ua nyob rau hauv Suav teb, thawj-chav kawm kev pabcuam, txiav-edge zoo, ntiaj teb-nrov npe

1. Cov teebmeem ntawm qhov ntsuas: Peb lub tuam txhab muaj cov khoom siv loj thiab lub Hoobkas hlau loj, ua tiav cov teebmeem ntawm qhov ntsuas hauv kev thauj mus los thiab kev yuav khoom, thiab dhau los ua lub tuam txhab hlau uas koom ua ke kev tsim khoom thiab kev pabcuam

2. Kev sib txawv ntawm cov khoom: Kev sib txawv ntawm cov khoom, txhua yam hlau uas koj xav tau tuaj yeem yuav tau los ntawm peb, feem ntau koom nrog cov qauv hlau, cov hlau rails, cov hlau sheet piles, photovoltaic brackets, channel steel, silicon steel coils thiab lwm yam khoom, uas ua rau nws yooj ywm dua Xaiv hom khoom xav tau kom tau raws li qhov xav tau sib txawv.

3. Kev muab khoom ruaj khov: Muaj cov kab tsim khoom thiab cov saw hlau ruaj khov dua tuaj yeem muab kev muab khoom txhim khu kev qha dua. Qhov no tseem ceeb heev rau cov neeg yuav khoom uas xav tau cov hlau ntau.

4. Kev cuam tshuam ntawm hom lag luam: Muaj kev cuam tshuam ntau dua rau hom lag luam thiab kev ua lag luam loj dua

5. Kev Pabcuam: Ib lub tuam txhab hlau loj uas koom ua ke kev hloov kho, kev thauj mus los thiab kev tsim khoom

6. Kev sib tw nqi: tus nqi tsim nyog

* Xa email mus rau[email tiv thaiv]kom tau txais ib daim ntawv hais txog koj cov haujlwm

COV NEEG SIV KHOOM MUS SAIB