Cov Hlau Silicon Suav / Cov Hlau Uas Muaj Cov Nplej ...

Cov Lus Qhia Txog Khoom

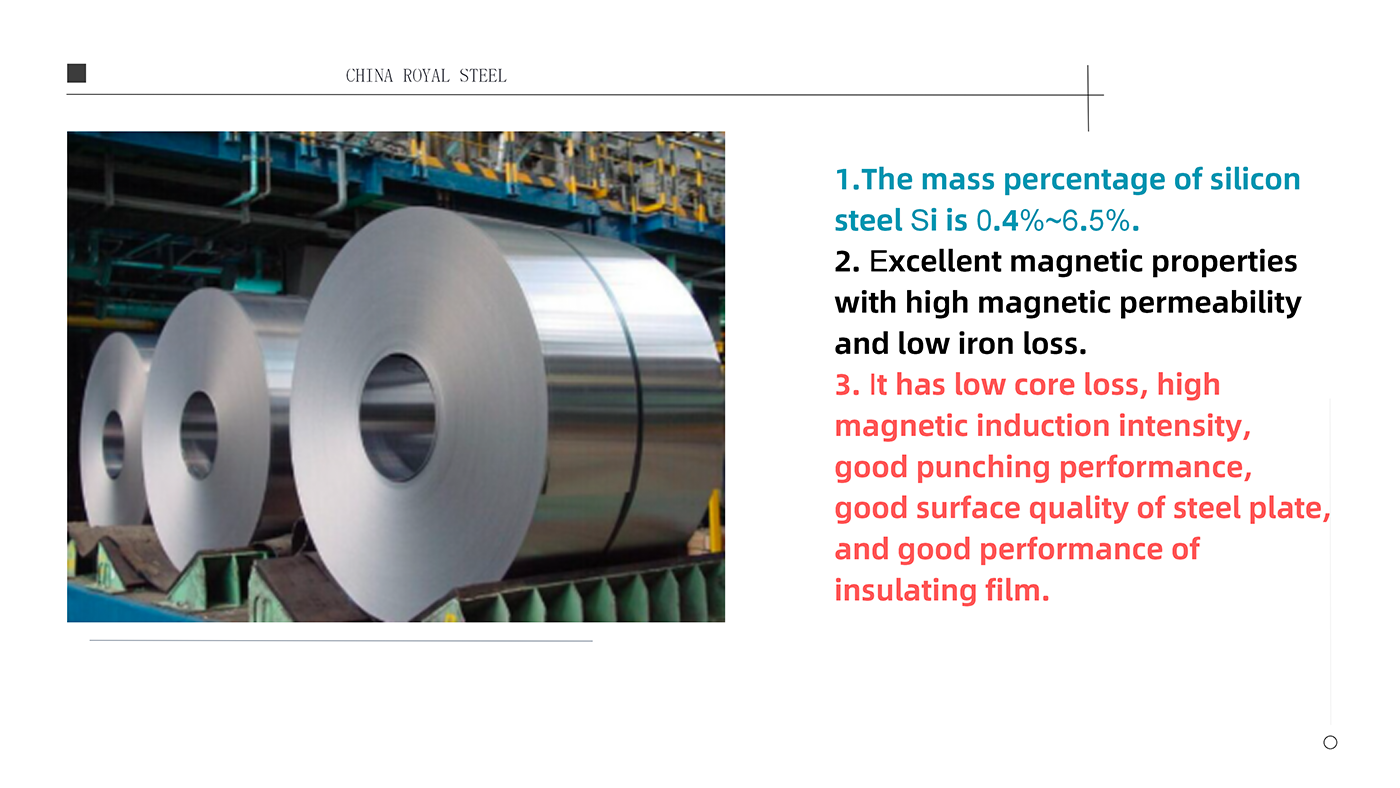

Cov khoom siv hlau silicon yog cov khoom siv hluav taws xob sib xyaw nrog cov permeability siab magnetic. Nws lub ntsiab feature yog tias nws qhia txog cov nyhuv magnetostrictive thiab hysteresis hauv lub magnetic teb. Tib lub sijhawm, cov khoom siv hlau silicon muaj qhov poob magnetic tsawg thiab qhov siab saturation magnetic induction zog, thiab yog tsim rau kev tsim cov khoom siv hluav taws xob ua haujlwm siab, qis poob.

Cov yam ntxwv

Cov khoom siv hlau silicon yog cov khoom siv uas tsis tshua muaj zog, yog li cov hluav taws xob tuaj yeem ntws hauv nws yam tsis muaj kev poob zog. Tib lub sijhawm, cov khoom siv hlau silicon muaj cov thermal conductivity zoo thiab tuaj yeem tso cua sov sai sai kom tsis txhob muaj kev puas tsuaj los ntawm cov hluav taws xob overheating.

| Lub Npe Lag Luam | Lub npe tuab (hli) | 密度 (kg/dm³) | Qhov Ceev (kg / dm³)) | Qhov tsawg kawg nkaus magnetic induction B50 (T) | Qhov tsawg kawg nkaus stacking coefficient (%) |

| B35AH230 | 0.35 | 7.65 | 2.30 | 1.66 | 95.0 |

| B35AH250 | 7.65 | 2.50 | 1.67 | 95.0 | |

| B35AH300 | 7.70 | 3.00 | 1.69 | 95.0 | |

| B50AH300 | 0.50 | 7.65 | 3.00 | 1.67 | 96.0 |

| B50AH350 | 7.70 | 3.50 | 1.70 | 96.0 | |

| B50AH470 | 7.75 | 4.70 | 1.72 | 96.0 | |

| B50AH600 | 7.75 | 6.00 | 1.72 | 96.0 | |

| B50AH800 | 7.80 | 8.00 | 1.74 | 96.0 | |

| B50AH1000 | 7.85 | 10.00 | 1.75 | 96.0 | |

| B35AR300 | 0.35 | 7.80 | 2.30 | 1.66 | 95.0 |

| B50AR300 | 0.50 | 7.75 | 2.50 | 1.67 | 95.0 |

| B50AR350 | 7.80 | 3.00 | 1.69 | 95.0 |

Daim Ntawv Thov

Cov khoom siv hlau silicon muaj kev tiv thaiv corrosion zoo, hnav tsis kam thiab qaug zog. Nws cov qauv khoom yog sib xws thiab ntom, thiab nws cov txheej yog tawv thiab ruaj khov thiab tsis yooj yim poob tawm. Tib lub sijhawm, cov khoom siv hlau silicon muaj cov khoom ua tau zoo thiab tuaj yeem ua tiav rau ntau yam duab thiab cov lus qhia los ntawm kev dov txias thiab lwm txoj hauv kev, ua rau nws yooj yim rau kev tsim ntau yam khoom siv fais fab.

Ntim & Xa Khoom

Cov khoom siv hlau silicon yuav tsum tau them sai sai rau cov dej noo thiab kev co thaum lub sijhawm thauj mus los. Ua ntej tshaj plaws, cov khoom ntim khoom yuav tsum muaj qee yam kev ua haujlwm tsis muaj dej noo, xws li kev siv cov ntawv cardboard tsis muaj dej noo lossis ntxiv cov neeg sawv cev nqus dej noo; Qhov thib ob, thaum lub sijhawm ntim khoom, cov khoom yuav tsum sim zam kev sib cuag ncaj qha nrog av thiab lwm yam khoom tawv, txhawm rau tiv thaiv kev puas tsuaj los ntawm kev co lossis kev rho tawm thaum lub sijhawm thauj mus los.

Cov Lus Nug Feem Ntau

Q1. Koj lub Hoobkas nyob qhov twg?

A1: Peb lub tuam txhab lub chaw ua haujlwm nyob hauv Tianjin, Suav teb. Uas tau nruab nrog ntau hom tshuab, xws li tshuab txiav laser, tshuab polishing iav thiab lwm yam. Peb tuaj yeem muab ntau yam kev pabcuam raws li cov neeg siv khoom xav tau.

Q2. Koj lub tuam txhab cov khoom tseem ceeb yog dab tsi?

A2: Peb cov khoom tseem ceeb yog stainless hlau phaj / ntawv, kauj, puag ncig / square yeeb nkab, bar, channel, steel sheet pile, steel strut, thiab lwm yam.

Q3. Koj tswj qhov zoo li cas?

A3: Daim Ntawv Pov Thawj Xeem Zeb tau muab nrog cov khoom xa tuaj, Kev Tshuaj Xyuas Sab Nraud muaj.

Q4. Cov txiaj ntsig ntawm koj lub tuam txhab yog dab tsi?

A4: Peb muaj ntau tus kws tshaj lij, cov neeg ua haujlwm txawj, cov nqi sib tw ntau dua thiab

kev pabcuam tom qab zoo tshaj plaws dua li lwm lub tuam txhab ua hlau tsis xeb.

Q5. Muaj pes tsawg lub teb chaws koj twb xa tawm lawm?

A5: Xa tawm mus rau ntau tshaj 50 lub teb chaws feem ntau yog los ntawm Asmeskas, Russia, UK, Kuwait,

Tim lyiv teb chaws, Qaib ntxhw, Jordan, Is Nrias teb, thiab lwm yam.

Q6. Koj puas muab tau qauv?

A6: Cov qauv me me hauv khw thiab tuaj yeem muab cov qauv dawb. Cov qauv customized yuav siv sijhawm li 5-7 hnub.