-

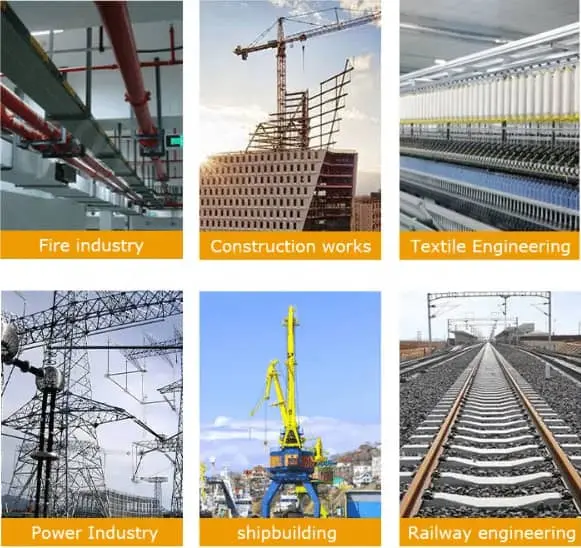

1. Daim ntawv thov:Kev xa dej thiab roj xa tawm, steel qauv, kev tsim kho.

-

2.ROYAL GROUP ERW / Welded Round Carbon Steel Pipes:Cov khoom zoo, txhim khu kev qha, dav siv hauv steel qauv thiab kev tsim kho.

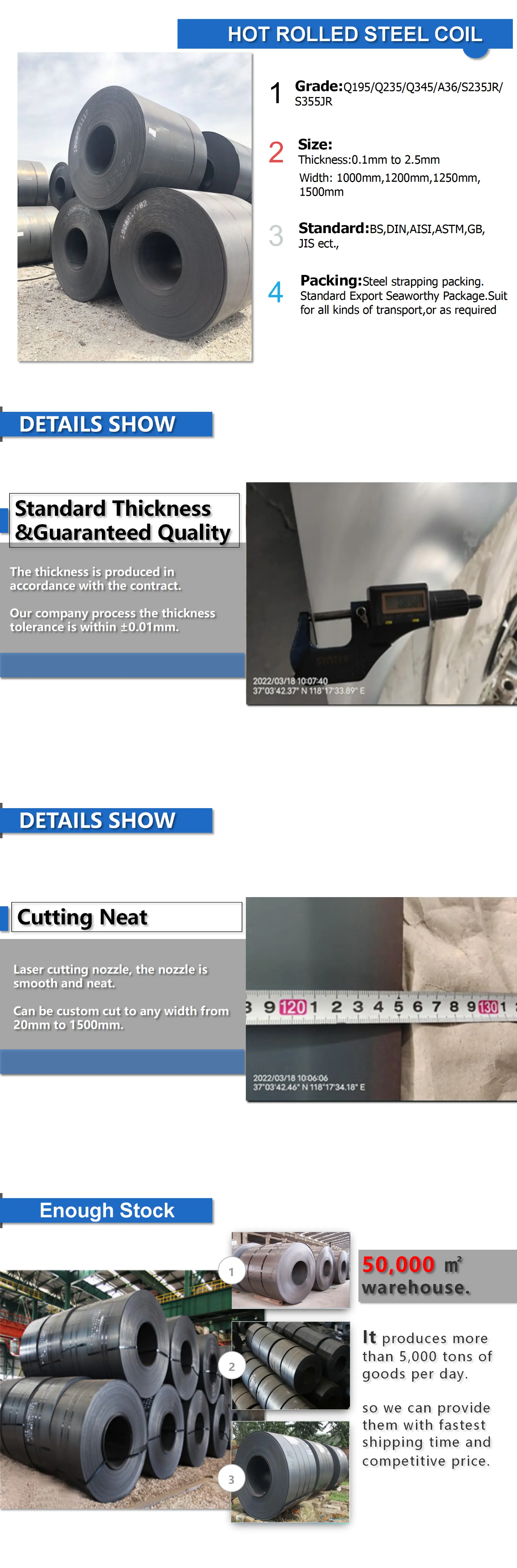

Tuam Tshoj Hoobkas Kub Rolled Carbon Steel Chev

Product Detail

| Khoom npe | Hotselling Qhov Zoo Tshaj Plaws Loj LojKub Rolled Steel Chev |

| Khoom siv | Q195/Q235/Q345/A36/S235JR/S355JR |

| Thickness | 1.5mm ~ 24mm |

| Loj | 3x1219mm 3.5x1500mm 4x1600mm 4.5x2438mm customized |

| Txuj | ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, |

| 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 | |

| Qib | A53-A369, Q195-Q345, ST35-ST52 |

| Qib A, Qib B, Qib C | |

| Cov txheej txheem | Kub dov |

| Ntim | Ntim, lossis nrog txhua yam xim PVC lossis raws li koj xav tau |

| Cov yeeb nkab kawg | Plain kawg / Beveled, tiv thaiv los ntawm lub kaus mom yas ntawm ob qho kawg, txiav quare, grooved, threaded thiab coupling, thiab lwm yam. |

| MOQ | 1 Tons, ntau tus nqi yuav qis dua |

| Kev kho saum npoo | 1. Mill tiav / Galvanized / stainless hlau |

| 2. PVC, Dub thiab xim pleev xim | |

| 3. Cov roj pob tshab, cov roj tiv thaiv xeb | |

| 4. Raws li cov neeg siv khoom xav tau | |

| Khoom siv | 1. Kev tsim cov qauv tsim, |

| 2. lifting machinery, | |

| 3. engineering, | |

| 4. Kev ua liaj ua teb thiab kev tsim kho tshuab, | |

| Keeb kwm | Tianjin Tuam Tshoj |

| Daim ntawv pov thawj | ISO9001-2008, SGS.BV, TUV |

| Lub sij hawm xa tuaj | Feem ntau hauv 10-15 hnub tom qab tau txais cov nyiaj them ua ntej |

Daim ntawv thov tseem ceeb

Nco tseg:

-

1. Kev Pabcuam:Cov qauv dawb, tag nrho tom qab-muag kev lees paub zoo, txhawb txhua txoj kev them nyiaj.

-

2.Customization:Txhua puag ncig carbon steel yeeb nkab specifications muaj (OEM & ODM) ntawm Hoobkas nqi los ntawm ROYAL GROUP.

Daim Ntawv Loj

| Thickness (hli) | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | customized |

| Dav (mm) | 800 | 900 | 950 ua | 1000 | 1219 | 1000 | customized |

Txheej txheem ntau lawm

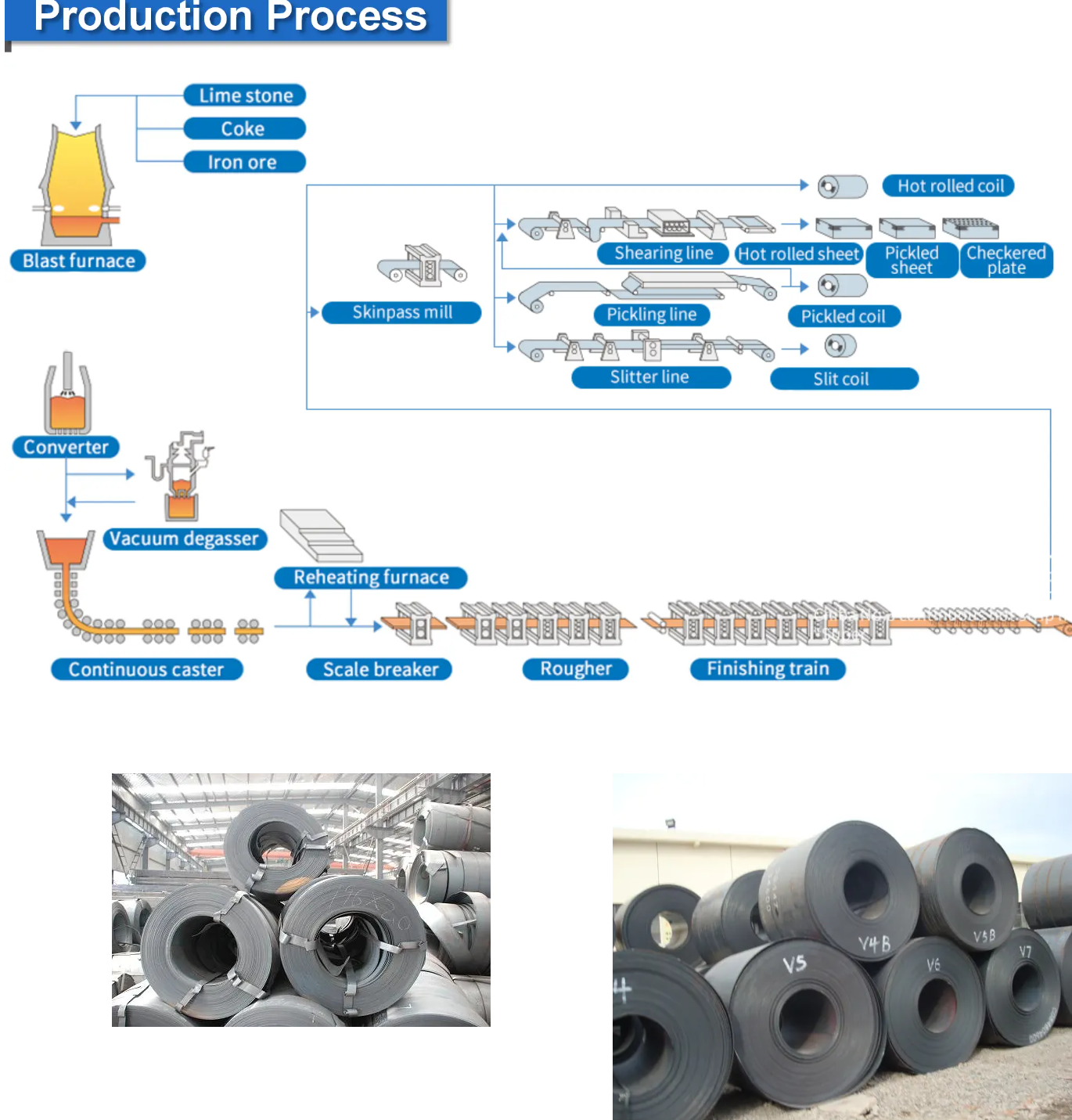

Cov txheej txheem ntau lawm ntawm kub-kuav los tiagsteel kaujyog qhov txuas tseem ceeb hauv kev tsim steel hlau. Nws tsuas yog tsim cov hlau billet rau hauv lub phaj uas xav tau los ntawm kev kub kub dov. Cov hauv qab no yog nws cov kauj ruam tseem ceeb:

Kub Rolled Steel Ntau Lawm Txheej Txheem (Simplified)

-

Raw Khoom Npaj:Pib nrog nruam nrum slabs los yog billets (150-300 mm tuab). Cov npoo yog ntxuav ntawm nplaim taws los yog sib tsoo kom tshem tawm cov nplai thiab qhov tsis xws luag.

-

Cua sov:Slabs yog rhuab nyob rau hauv ib tug taug kev beam rauv rau 1100-1300 ° C rau austenitization, kom ntseeg tau ductility. Qhov kub thiab txias sib xws yog tswj tau lub sijhawm.

-

Roughing:Slabs dhau los ntawm reversing roughing mills kom txo thickness mus rau 30-50 mm. High-pressure water descaling tshem tawm cov oxides saum npoo.

-

Ua tiav:Cov kab nruab nrab yog dov hauv cov mills tiav rau lub hom phiaj tuab (1.2-25 hli). AGC thiab flatness tswj xyuas kom meej qhov tseeb. Rolls yog txias thiab lubricated los tiv thaiv hnav thiab deformation.

-

Cua txias:Laminar txias txo qhov kub ntawm qhov kub ntawm ~ 800 ° C mus rau chav tsev kub (30-50 ° C / sec), tswj microstructure thiab txhua yam khoom.

-

Coiling:Cov strips raug mob rau hauv coils nyob rau hauv kev tswj nruj (100-500 N / mm²) ntawm 550-700 ° C rau cov duab thiab cov khoom zoo.

-

Tom qab ua tiav:Kev xaiv kev kho mob muaj xws li pickling, galvanizing / aluminizing, annealing rau ductility, thiab flattening rau nto tiav.

-

Kev soj ntsuam zoo & ntim:Cov khoom kawg raug kuaj xyuas qhov ntev, cov khoom siv kho tshuab, thiab qhov zoo ntawm qhov chaw ua ntej coiling, bundling, thiab daim ntawv lo rau ib tus neeg siv khoom tshwj xeeb.

Ntim thiab thauj

Feem ntau liab qab pob

Kev thauj mus los:Kev nthuav qhia (Sample Delivery), Cua, Rail, Av, Hiav Txwv shipping (FCL lossis LCL lossis Tej)

FAQ

Q: Koj puas yog cov chaw tsim khoom?

A:Yog lawm, peb yog cov chaw tsim khoom ntawm kauv steel raj raws li hauv Tianjin, Suav.

Q: Kuv puas tuaj yeem tso qhov kev txiav txim me me ntawm ob peb tons?

A:Muaj tseeb tiag. Peb tuaj yeem xa cov xaj me me uas siv LCL (Less than Container Load) kev pabcuam.

Q: Puas yog kuaj dawb?

A:Yog lawm, kuaj dawb, tab sis tus neeg yuav khoom them tus nqi thauj khoom.

Q: Koj puas yog tus neeg muag khoom tau lees paub thiab koj puas lees txais kev lees paub kev lag luam?

A:Yog lawm, peb yog ib tus neeg muab khoom kub xya xyoo thiab lees txais Trade Assurance.