Lub Hoobkas ncaj qha GB Standard Round Bar yog tus nqi zoo

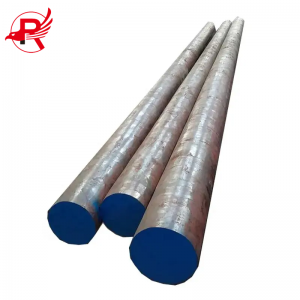

Hlau pas nrigyog ib yam khoom siv hlau uas muaj zog thiab corrosion kuj.

Feem ntau siv hauv kev tsim kho, tshuab, nkoj thiab lwm yam lag luam. Hauv kev tsim kho kev lag luam, steel rods tuaj yeem siv los txhawb cov pob zeb ua vaj tse xws li ntaiv, choj, cov plag tsev, thiab lwm yam. steel rods kuj tseem siv tau los ua cov khoom siv kho tshuab, xws li bearings, gears, bolts, thiab lwm yam. Tsis tas li ntawd, steel rods kuj tseem siv tau rau hauv lub hauv paus engineering, tunnel engineering, water conservancy engineering thiab lwm yam.

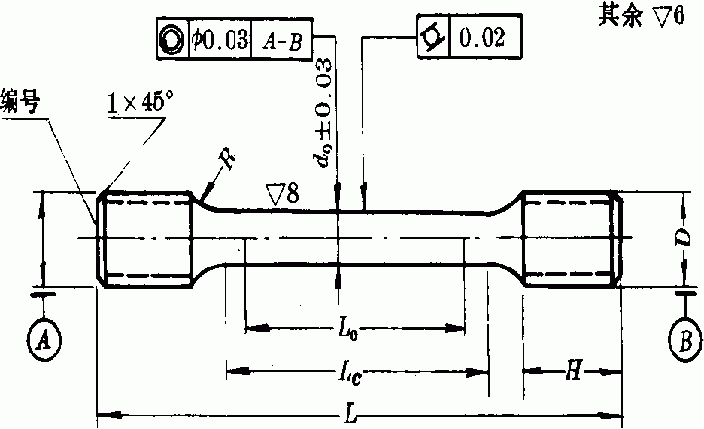

Cov ntsiab lus ntawm cov pas nrig steel feem ntau suav nrog cov lus qhia hauv qab no: txoj kab uas hla, sab ntev, ntev, thiab lwm yam tau teev tseg raws li qhov xav tau ntawm engineering.

PRODUCTION PROCESS

1. Kev npaj cov khoom siv raw

1. Kev xaiv cov khoom siv: Xaiv cov hlau zoo uas muaj cov khoom zoo, tsis muaj oxide nplai, tsis muaj kab nrib pleb lossis tawg, thiab ob peb impurities li raw khoom.

2. Txiav: Txiav cov ntaub ntawv raw rau hauv qhov ntev thiab txoj kab uas hla, kom ntseeg tau tias qhov chaw txiav yog ci thiab tawg-dawb.

2. Kev kho kom zoo

1. Kev tshem tawm impurity: Siv cov khoom sib nqus sib nqus los yog phau ntawv txheeb xyuas kom tshem tawm cov impurities hauv cov khoom siv raw.

2. Preheating: cua sov cov ntaub ntawv raw mus rau qhov kub thiab txias hauv qhov cub rau kev ua haujlwm tom ntej.

3. Refining: Muab cov khoom siv preheated rau hauv qhov cub refining rau kev kho kub kub kom tshem tawm cov teeb meem xws li carbon, sulfur, thiab phosphorus hauv cov khoom siv raw, thiab kho cov ntsiab lus carbon.

3. Kev ua thiab kev tsim

1. Preforming: Ua cov khoom ua kom zoo rau hauv cov tuav ntawm ib qho zoo.

2. Kev kho cua sov: Kub lub pas nrig preformed rau qhov kub thiab txias thiab khaws cia rau ib lub sijhawm los kho cov khoom siv ntawm tus pas nrig.

3. Txias: Muab tus pas ntsuas kub tso rau hauv cov huab cua kom txias ib txwm.

4. Tiav: Lubsteel round baryog ntxiv rau kev ua haujlwm zoo xws li xaim txiav thiab polishing kom ua tiav qhov siab dua thiab qhov zoo.

PRODUCT SIJE

| SPECIFICATIONS RAU STEEL BAR | |

| 1. Loj | 1) 6-12M lossis cov neeg siv khoom xav tau |

| 2) Txoj kab uas hla: customized | |

| 3) Steel Bar, Square / Rectangular Bar, Deformed steel bar | |

| 2. Txuj: | ASTM, DIN, GB, JIS,EN |

| 3. Khoom siv | Q235, Q355, 20,45,40Cr, HRB400, HRB500 |

| 4. Qhov chaw ntawm peb lub Hoobkas | Tianjin, Suav teb |

| 5. Kev siv: | 1) Khoom siv hauv tsev |

| 2) Ua thiab tsim cov khoom siv kho tshuab | |

| 3) Ua cov bearings | |

| 6. Txheej: | 1) Bared 2) Dub Painted (cov kua roj vanish txheej) 3) galvanized |

| 7. Cov txheej txheem: | kub dov |

| 8. Hom: | Carbon Steel Bar |

| 9. Tshooj puab: | puag ncig |

| 10. Kev tshuaj xyuas: | Kev tshuaj xyuas cov neeg siv khoom lossis kev tshuaj xyuas los ntawm 3rd tog. |

| 11. Kev xa khoom: | Thawv, Bulk Vessel. |

| 12. Txog Peb Qhov Zoo: | 1) Tsis muaj kev puas tsuaj, tsis khoov 2) Dawb rau oiled & cim 3) Tag nrho cov khoom tuaj yeem raug kuaj xyuas los ntawm tus neeg thib peb tshuaj xyuas ua ntej xa khoom |

| Round steel qws khoom lub rooj | |||||

| txoj kab uas hla mm | Tshooj cm xo | unit loj kg/m | txoj kab uas hla mm | Tshooj cm xo | unit loj kg/m |

| 6 | 0.283 ib | 0.222 ib | (45) | 15.9 ib | 12.5 ib |

| 7 | 0.385 ib | 0.302 ib | 46 | 16.6 | 13.0 Nws |

| 8 | 0.503 ib | 0.395 ib | 48 | 18.1 | 14.2 |

| 9 | 0.636 ib | 0.499 ib | 50 | 19.6 ib | 15.4 ib |

| 10 | 0.785 ib | 0.617 ib | (52) | 21.2 | 16.7 ib |

| 11 | 0.950 ib | 0.746 ib | 55 | 23.8 ib | 18.7 ib |

| 12 | 1.13 | 0.888 ib | 56 | 24.6 ib | 19.3 ib |

| 13 | 1.33 | 1.04 ib | 60 | 28.3 ib | 22.2 |

| (14) | 1.54 ib | 1.21 | 64 | 32.2 ib | 25.3 |

| 16 | 2.01 Nws | 1.58 ib | 65 | 33.2 ib | 26.0 Nws |

| (18) | 2.55 Nws | 2.00 Nws | (68) | 36.3 ib | 28.5 Nws |

| 19 | 2.84 ib | 2.23 | 70 | 38.5 ib | 30.2 ib |

| 20 | 3.14 | 2.47 ib | 75 | 44.2 ib | 34.7 ib |

| 22 | 3.80 ib | 2.98 ib | 80 | 50.3 | 39.5 ib |

| 24 | 4.52 ib | 3.55 Nws | 85 | 56.8 ua | 44.6 ib |

| 25 | 4.91 ib | 3.85 ib | 90 | 63.6 ib | 49.9 ib |

| (27) | 5.73 ib | 4.50 Nws | 95 | 70.9 ua | 55.6 ib |

| 28 | 6.16 | 4.83 ib | 100 | 78.5 ib | 61.7 ib |

| 30 | 7.07 ib | 5.55 ib | 110 | 95.0 ua | 74.6 ib |

| 32 | 8.04 ib | 6.31 Nws | 120 | 113 | 88.7 ua |

| (33) | 8.55 Nws | 6.71 ib | 130 | 133 | 104 |

| 36 | 10.2 | 7.99 ib | 140 | 154 | 121 |

| 38 | 11.3 | 8.90 ib | 150 | 177 | 139 |

| (39) | 11.9 ib | 9.38 ib | 160 | 201 | 158 |

| 42 | 13.9 Nws | 10.9 | 180 | 255 | 200 |

| 200 | 314 | 247 | |||

GB Txheem Round Bar

Specification: Q235, Q355, 20, 45, 40Gr

Txuj: GB / T 1499.2-2007

GB/T 1499.3-2010

Loj: 6-12M lossis cov neeg siv khoom xav tau

| Txoj kab uas hla (mm) | Qhov hnyav ib ' meter ' (kg / m | Daim ib pob | Nonimal nyhav ib pob ntawm 12 meter (Metric ton) mus |

| 5.5 | 0.187 ib | 450 | 1.010 Nws |

| 6.0 | 0.222 ib | 375 | 0.999 ib |

| 6.5 | 0.260 Nws | 320 | 0.998 ib |

| 7.0 ib | 0.302 ib | 276 | 1.000 |

| 8.0 ib | 0.395 ib | 200 | 0.948 ib |

| 9.0 ib | 0.499 ib | 168 | 1.006 ib |

| 10.0 | 0.617 ib | 138 | 1.022 ib |

| 12.0 Nws | 0.888 ib | 96 | 1.023 ib |

NTA

GB Txheem Round Barmuaj zog thiab hardness. Piv nrog rau lwm cov ntaub ntawv, steel rods muaj zog dua thiab muaj peev xwm tiv taus ntau zog thiab siab. Qhov no tso cai rau cov pas nrig steel ua lub luag haujlwm zoo dua hauv ntau txoj haujlwm, muab kev txhawb nqa ruaj khov thiab txhim khu kev qha.

Steel rods muaj zoo corrosion kuj. Cov pas nrig hlau tuaj yeem tiv taus ntev ntev rau qhov chaw hnyav xws li av noo, acid thiab alkali yam tsis muaj kev puas tsuaj. Qhov no tso cai rau cov pas nrig steel tswj nws cov kev ua tau zoo thiab kev ruaj ntseg nyob rau hauv ntau qhov chaw, ncua nws lub neej kev pab cuam.

Cov pas nrig steel kuj muaj kev ua haujlwm zoo. Steel rods tuaj yeem ua tiav thiab zoo li tus qauv los ntawm kev kho cua sov, kev ua haujlwm txias, thiab lwm yam, kom tau raws li qhov sib txawv engineering thiab kev tsim khoom. Qhov no tso cai rau cov pas nrig steel tuaj yeem siv tau yooj yim hauv ntau txoj haujlwm, txhim kho kev ua haujlwm thiab ua haujlwm zoo.

Steel rods muaj ntau yam kev siv thiab zoo. Hauv kev tsim kho, kev tsim khoom thiab kev thauj mus los, steel rods ua lub luag haujlwm tseem ceeb. Nws lub zog siab, corrosion kuj thiab machinability ua steel rods xaiv cov khoom siv zoo tshaj plaws los muab kev txhawb nqa ruaj khov, txhim khu kev qha thiab ruaj khov. Steel rods muaj dav daim ntawv thov kev cia siab nyob rau hauv ntau yam teb thiab yuav txuas ntxiv mus ua lub luag hauj lwm tseem ceeb.

APPLICATION

Cov vaj tse thiab cov vaj tsev:carbon steel round bartuaj yeem siv rau kev ntxiv dag zog thiab kev txhawb nqa cov tsev thiab cov vaj tse, xws li kev ntxiv dag zog rau cov kab teeb ci, kab thiab cov hauv paus.

txoj kev thiab cov choj: steel rods tuaj yeem siv rau kev tsim kho txoj kev thiab Choj, xws li kev txhawb nqa thiab kev txhawb nqa ntawm piers, choj arches, tunnels thiab railway lem.

Tsheb thiab tsheb: steel rods tuaj yeem siv rau hauv kev tsim tsheb thiab lwm yam tsheb xws li kev txhawb nqa lub log, chassis thiab lub cev.

Manufacturing: steel rods yog dav siv nyob rau hauv kev tsim kev lag luam thiab yuav siv tau los ua machinery, khoom thiab cov cuab yeej xws li Hoobkas khoom, ua liaj ua teb machinery thiab tej cuab yeej.

Aerospace: Hlau rods tuaj yeem siv rau hauv kev lag luam aerospace, piv txwv li hauv kev tsim cov qauv thiab cov khoom siv rau cov dav hlau, foob pob hluav taws thiab satellites.

Cov rooj tog zaum thiab kho kom zoo nkauj: steel rods tuaj yeem siv rau rooj tog thiab kho kom zoo nkauj, xws li ua rooj, rooj zaum, txaj ncej thiab teeb.

Cov khoom siv ua kis las: Cov pas nrig hlau tuaj yeem siv los ua cov khoom siv kis las, xws li golf clubs, tennis rackets thiab tsheb kauj vab ncej.

Tag nrho cov nyob rau hauv tag nrho, steel rods ua lub luag hauj lwm tseem ceeb heev nyob rau hauv ntau yam lag luam thiab teb, thiab lawv lub zog siab, corrosion kuj thiab plasticity ua rau lawv yog ib qho tseem ceeb heev cov khoom.

PACKAGING THIAB SHIPPING

Ntim:

Steel pas nrig stack nrees:kub dov steel round barpawg zoo zoo, ruaj khov, kom ntseeg tau tias steel pas nrig sib dhos, tiv thaiv steel pas nrig instability. Siv cov hlua khi lossis cov hlua khi kom ruaj khov thiab tiv thaiv kev txav mus los thaum thauj.

Siv cov ntim khoom tiv thaiv: qhwv cov pas hlau hauv cov khoom pov thawj noo noo, xws li cov ntawv yas lossis cov ntawv tsis muaj dej, los tiv thaiv lawv ntawm dej, av noo thiab lwm yam ib puag ncig. Qhov no yuav pab tiv thaiv xeb thiab corrosion.

Shipping:

Xaiv txoj kev thauj mus los: Raws li tus naj npawb thiab qhov hnyav ntawm steel rods, xaiv txoj kev tsheb thauj mus los, xws li cov tsheb thauj khoom, cov thawv ntim, nkoj, thiab lwm yam. Xav txog yam xws li kev ncua deb, sijhawm, nqi, thiab cov kev cai tsheb.

Siv cov cuab yeej nqa khoom tsim nyog: Thaum thauj khoom thiab tshem tawm cov pas nrig steel, yuav tsum siv cov cuab yeej nqa tsim nyog, xws li cranes, forklifts, loaders, thiab lwm yam. Ua kom cov khoom siv muaj peev xwm txaus los tiv thaiv qhov hnyav ntawm cov pas nrig steel.

Kev thauj khoom ruaj khov: Siv cov hlua khi, hlua khi lossis lwm txoj hauv kev tsim nyog kom ruaj ntseg cov hlua khi rau lub tsheb thauj mus los kom tsis txhob txav mus los, zawv zawg lossis poob thaum thauj.

COMPANY HUV

Ua nyob rau hauv Tuam Tshoj, thawj-chav kev pab cuam, txiav-ntug zoo, ntiaj teb no-renowned

1. Scale effect: Peb lub tuam txhab muaj cov saw hlau loj thiab lub Hoobkas steel loj, ua tiav cov txiaj ntsig hauv kev thauj mus los thiab kev yuav khoom, thiab dhau los ua ib lub tuam txhab steel uas koom ua ke ntau lawm thiab kev pabcuam.

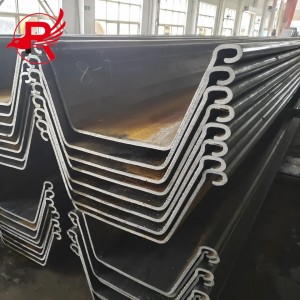

2. Cov khoom sib txawv: Cov khoom sib txawv, txhua yam hlau koj xav tau tuaj yeem yuav los ntawm peb, feem ntau koom nrog cov qauv steel, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils thiab lwm yam khoom, uas ua rau nws yooj yim xaiv cov khoom uas xav tau kom tau raws li cov kev xav tau sib txawv.

3. Cov khoom ruaj khov: Muaj cov kab ntau lawm ruaj khov thiab cov saw hlau tuaj yeem muab cov khoom siv txhim khu kev qha. Qhov no yog qhov tshwj xeeb tshaj yog rau cov neeg yuav khoom uas xav tau ntau cov hlau.

4. Hom kev cuam tshuam: Muaj ntau hom kev cuam tshuam thiab kev lag luam loj dua

5. Kev Pabcuam: Lub tuam txhab hlau loj uas sib xyaw ua ke, kev thauj mus los thiab kev tsim khoom

6. Tus nqi sib tw: tus nqi tsim nyog

* Xa email rau[email tiv thaiv]kom tau txais cov lus hais rau koj qhov project

Cov neeg tuaj xyuas

FAQ

1.Kuv tuaj yeem tau txais cov lus hais los ntawm koj li cas?

Koj tuaj yeem tso peb cov lus, thiab peb yuav teb txhua cov lus hauv lub sijhawm.

2.Koj puas tuaj yeem xa cov khoom raws sijhawm?

Yog lawm, peb cog lus tias yuav muab cov khoom zoo tshaj plaws thiab xa khoom raws sijhawm. Kev ncaj ncees yog peb lub tuam txhab txoj cai.

3.Kuv puas tuaj yeem tau txais cov qauv ua ntej xaj?

Yog lawm, tau kawg. Feem ntau peb cov qauv dawb, peb tuaj yeem tsim los ntawm koj cov qauv lossis cov duab kos duab.

4.Koj cov nqe lus them nqi yog dab tsi?

Peb lub sijhawm them nyiaj ib txwm yog 30% tso nyiaj, thiab so tawm tsam B / L. EXW, FOB, CFR, CIF.

5.Koj puas lees txais qhov kev tshuaj xyuas thib peb?

Yog lawm peb lees txais.

6.Peb ntseeg koj lub tuam txhab li cas?

Peb tshwj xeeb hauv kev lag luam steel rau xyoo raws li tus neeg muag khoom kub, lub hauv paus chaw nyob hauv Tianjin xeev, txais tos los tshawb xyuas txhua txoj hauv kev, los ntawm txhua txoj kev.