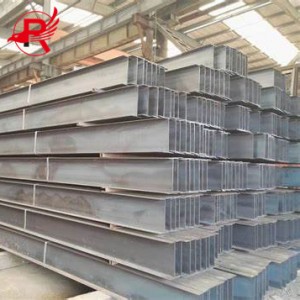

ASTM H-Zoo Li Hlau H Beam | Kub Dov H-Beam rau Cov Kem Hlau & Seem

ASTM A36 H beamyog ib hom hlau ua los ntawm cov hlau carbon, uas yog ib yam khoom siv dav dav thiab siv tau ntau yam uas paub txog nws lub zog siab thiab ruaj khov. H-beams yog tus cwj pwm los ntawm lawv cov duab "H", uas muab lub peev xwm thauj khoom zoo heev thiab kev txhawb nqa hauv ntau yam kev tsim kho thiab kev siv engineering. Nrog nws cov khoom zoo tshaj plaws, carbon steel H-beam feem ntau siv rau hauv kev tsim kho vaj tse, choj, thiab lwm yam haujlwm tsim kho vaj tse. Nws muab kev daws teeb meem pheej yig thiab txhim khu kev qha rau kev tsim cov qauv ruaj khov thiab rov ua dua tshiab, ua rau nws yog qhov kev xaiv nrov hauv kev lag luam kev tsim kho. Lub zog thiab weldability ntawm carbon steel ntxiv txhim kho nws qhov kev tsim nyog rau cov ntawv thov hnyav, ua rau H-beams yog qhov kev xaiv nyiam rau cov engineers thiab cov neeg tsim kho nrhiav cov ntaub ntawv tsim kho uas ntseeg tau thiab ua haujlwm tau zoo.

Cov ntsiab lus ntawm ib qho ntawm cov hlau kub dov h beam feem ntau muaj cov lus qhia hauv qab no:

Qhov Loj: Qhov loj thiab qhov ntev ntawm H-Beam, xws li qhov ntev, dav, thiab tuab, tau teev tseg raws li qhov xav tau ntawm qhov project.

Cov yam ntxwv ntawm kev txiav: Cov yam ntxwv tseem ceeb ntawm H-Beam suav nrog thaj chaw, lub zog ntawm inertia, section modulus, thiab qhov hnyav ib chav ntev. Cov yam ntxwv no yog qhov tseem ceeb rau kev xam tus qauv tsim thiab kev ruaj khov ntawm lub pawg.

TXHEEJ TXHEEM TXOG KEV TSIM KHOOM

1. Kev npaj ua ntej: suav nrog kev yuav khoom siv raw, kev tshuaj xyuas zoo thiab kev npaj khoom siv. Cov khoom siv raw feem ntau yog cov hlau yaj uas tsim los ntawm lub cub tawg graphitization zoo lossis lub cub tawg hluav taws xob, uas raug muab tso rau hauv kev tsim khoom tom qab kev tshuaj xyuas zoo.

2. Kev Smelting: Ncuav cov hlau uas yaj rau hauv lub converter thiab ntxiv cov hlau rov qab los yog hlau npua rau kev ua hlau. Thaum lub sijhawm ua hlau, cov pa roj carbon thiab qhov kub ntawm cov hlau uas yaj raug tswj los ntawm kev kho qhov ntau ntawm cov neeg sawv cev graphitizing thiab tshuab cov pa oxygen hauv lub cub tawg.

3. Cov hlau nplaum tas mus li: Cov hlau nplaum raug nchuav rau hauv lub tshuab ua hlau nplaum tas mus li, thiab cov dej ntws los ntawm lub tshuab ua hlau nplaum tas mus li raug txhaj rau hauv lub tshuab crystallizer, cia cov hlau nplaum maj mam khov kho los ua ib daim hlau nplaum.

4. Kub dov: Lub billet casting tas mus li yog kub dov los ntawm lub tshuab kub dov kom nws mus txog qhov loj me thiab cov duab geometric.

5. Ua tiav dov: Lub billet kub-dov tiav lawm dov, thiab qhov loj me thiab cov duab ntawm lub billet tau ua kom raug dua los ntawm kev kho cov txheej txheem dov thiab tswj lub zog dov.

6. Txias: Cov hlau tiav lawm yog txias kom txo qhov kub thiab kho qhov ntev thiab cov khoom.

7. Kev tshuaj xyuas zoo thiab ntim khoom: Kev tshuaj xyuas zoo ntawm cov khoom tiav lawm thiab cov ntim khoom raws li qhov loj thiab ntau npaum li cas.

Qhov Loj ntawm Khoom

| Cov khoom | Kub dov H Beam |

| Qhov chaw keeb kwm | Hebei, Suav teb |

| Qib | Q235B/SS400/Q355B/S235JR/S355JR |

| Tus Qauv | ASTM / AISI / JIS / EN / DIN |

| Loj | Qhov Dav Dav ntawm Lub Vev Xaib: 100-912 hli |

| Dav ntawm lub flange: 50-302 hli | |

| Lub Vev Thickness: 5-18mm | |

| Flange Thickness: 7-34mm | |

| Cov hlau los yog tsis | Tsis yog Alloy |

| Kev Txawj Ntse | txias los yog kub dov |

| Kev Pabcuam Ua Haujlwm | Khoov, Vuam, Xuas Nrig, Txiav |

| Lub Sijhawm Xa Khoom | 31-45 hnub |

| Ntev | 1-12m |

| Kev them nqi | los ntawm qhov hnyav theoretical |

| Daim Ntawv Thov | kev tsim kho vaj tse thiab kev tsim kho vaj tse |

| Kev Them Nyiaj | T/T; |

| Qhov Loj ntawm H Beam | ||||

| Qhov Dav ntawm Lub Vev Xaib (hli) | Qhov Dav Ntawm Flange (hli) | Qhov tuab ntawm lub vev xaib (hli) | Flange Thickness (hli) | Qhov Hnyav Theoretical (kg/m3) |

| 100 | 50 | 5 | 7 | 9.54 |

| 100 | 100 | 6 | 8 | 17.2 |

| 125 | 60 | 6 | 8 | 13.3 |

| 125 | 125 | 6.5 | 9 | 23.8 |

| 150 | 75 | 5 | 7 | 14.3 |

| 148 | 100 | 6 | 9 | 21.4 |

| 150 | 150 | 7 | 10 | 31.9 |

| 175 | 90 | 5 | 8 | 18.2 |

| 175 | 175 | 7.5 | 11 | 40.4 |

| 194 | 150 | 6 | 9 | 31.2 |

| 198 | 99 | 4.5 | 7 | 18.5 |

| 200 | 100 | 5.5 | 8 | 21.7 |

| 200 | 200 | 8 | 12 | 50.5 |

| 200 | 204 | 12 | 12 | 56.7 |

| 244 | 175 | 7 | 11 | 44.1 |

| 248 | 124 | 5 | 8 | 25.8 |

| 250 | 125 | 6 | 9 | 29.7 |

| 250 | 250 | 9 | 14 | 72.4 |

| 250 | 255 | 14 | 14 | 82.2 |

| 294 | 200 | 8 | 12 | 57.3 |

| 294 | 302 | 12 | 12 | 85 |

| 298 | 149 | 5.5 | 8 | 32.6 |

| 300 | 150 | 6.5 | 9 | 37.3 |

| 300 | 300 | 10 | 15 | 94.5 |

| 300 | 305 | 15 | 15 | 106 |

| 340 | 250 | 9 | 14 | 79.7 |

| 344 | 348 | 10 | 16 | 115 |

| 346 | 174 | 6 | 9 | 41.8 |

| 350 | 175 | 7 | 11 | 50 |

| 350 | 350 | 12 | 19 | 137 |

| 388 | 402 | 15 | 15 | 141 |

| 390 | 300 | 10 | 16 | 107 |

| 394 | 398 | 11 | 18 | 147 |

| 396 | 199 | 7 | 11 | 56.7 |

| 400 | 200 | 8 | 13 | 66 |

| 400 | 400 | 13 | 21 | 172 |

| 400 | 408 | 21 | 21 | 197 |

| 414 | 405 | 18 | 28 | 233 |

| 428 | 407 | 20 | 35 | 284 |

| 440 | 300 | 11 | 18 | 124 |

| 446 | 199 | 8 | 12 | 66.7 |

| 450 | 200 | 9 | 14 | 76.5 |

| 458 | 417 | 30 | 50 | 415 |

| 482 | 300 | 11 | 15 | 115 |

| 488 | 300 | 11 | 18 | 129 |

| 496 | 199 | 9 | 14 | 79.5 |

| 498 | 432 | 45 | 70 | 605 |

| 500 | 200 | 10 | 16 | 89.6 |

| 506 | 201 | 11 | 19 | 103 |

| 582 | 300 | 12 | 17 | 137 |

| 588 | 300 | 12 | 20 | 151 |

| 594 | 302 | 14 | 23 | 175 |

| 596 | 199 | 10 | 15 | 95.1 |

| 600 | 200 | 11 | 17 | 106 |

| 606 | 201 | 12 | 20 | 120 |

| 692 | 300 | 13 | 20 | 166 |

| 700 | 300 | 12 | 24 | 185 |

| 792 | 300 | 14 | 22 | 191 |

| 800 | 300 | 14 | 26 | 210 |

| 890 | 299 | 15 | 23 | 213 |

| 900 | 300 | 16 | 28 | 243 |

| 912 | 302 | 18 | 34 | 286 |

QHOV ZOO

Qee cov yam ntxwv thiab cov yam ntxwv ntawm cov hlau carbonASTM A370 H beam:

- Muaj zog thiab ruaj khov: Cov hlau carbon yog paub txog nws lub zog siab thiab ruaj khov, ua rau H-beams muaj peev xwm txhawb nqa cov khoom hnyav thiab muab kev ruaj khov ntawm cov qauv.

- Siv Tau Ntau Yam: H-beams ua los ntawm cov hlau carbon muaj ntau yam thiab siv tau rau ntau yam haujlwm tsim kho, suav nrog cov thav duab tsev, choj, thiab lwm yam qauv.

- Muaj peev xwm ua tau zoo: Lub duab H tshwj xeeb ntawm lub nqaj muab lub peev xwm ua tau zoo, ua rau nws tsim nyog rau kev txhawb nqa ntau hom qauv.

- Kev Lag Luam:ASTM A572 H beammuab kev daws teeb meem pheej yig rau kev tsim kho thiab kev tsim kho vim yog cov khoom siv muaj thiab pheej yig.

- Weldable: Cov hlau carbon tuaj yeem yooj yim welded, tso cai rau kev tsim cov H-beams customized kom tau raws li cov kev xav tau tshwj xeeb ntawm cov haujlwm.

PROJECT

Peb lub tuam txhab muaj ntau xyoo ntawm kev paub txog kev lag luam txawv teb chaws ntawm H-beams. Tag nrho cov H-beams xa tawm mus rau Canada lub sijhawm no yog ntau dua 8,000,000 tons. Tus neeg siv khoom yuav tshuaj xyuas cov khoom hauv lub Hoobkas. Thaum cov khoom dhau qhov kev tshuaj xyuas, kev them nyiaj yuav raug ua thiab xa tawm. Txij li thaum kev tsim kho ntawm qhov project no pib, peb lub tuam txhab tau npaj cov phiaj xwm tsim khoom thiab sau cov txheej txheem kom ntseeg tau tias qhov project hlau H-puab xa tuaj raws sijhawm. Txij li thaum nws siv rau hauv cov tsev Hoobkas loj, cov kev cai ua tau zoo rau cov khoom hlau H-puab siab dua li qhov tsis kam tiv thaiv corrosion ntawm cov roj platform H-puab hlau. Yog li ntawd, peb lub tuam txhab pib los ntawm qhov chaw tsim khoom thiab nce kev tswj hwm ntawm kev ua hlau, kev sib txuas ntxiv thiab kev dov cov txheej txheem cuam tshuam. Txhawb kom zoo ntawm cov khoom ntawm ntau yam kev qhia kom raug tswj hwm hauv txhua yam, kom ntseeg tau tias 100% dhau tus nqi ntawm cov khoom tiav. Thaum kawg, qhov zoo ntawm kev ua cov hlau H-puab tau lees paub los ntawm cov neeg siv khoom, thiab kev koom tes ntev thiab kev sib pab tau ua tiav raws li kev ntseeg siab sib pab.

KEV TSHAWB XYUAS KHOOM

Rau cov khoom siv niaj hnubASTM A6 H beam, yog tias cov pa roj carbon yog 0.4% txog 0.7%, thiab cov khoom siv kho tshuab tsis siab heev, normalizing tuaj yeem siv ua kev kho cua sov kawg. Ua ntej, cov hlau ncej ntoo khaub lig yuav tsum tau tsim. Tom qab faib ua haujlwm hauv lub Hoobkas, lawv mam li sib sau ua ke, calibrated, thiab tshuaj xyuas kom ntseeg tau tias cov khoom tsim nyog thiab tom qab ntawd thauj mus rau thaj chaw tsim kho rau splicing. Thaum lub sijhawm splicing, qhov splicing yuav tsum tau ua raws li cov txheej txheem sib xws. , Tsuas yog txoj kev no thiaj li ua tau zoo ntawm cov khoom. Tom qab kev sib dhos tiav lawm, cov txiaj ntsig kev teeb tsa zaum kawg yuav tsum tau tshuaj xyuas. Tom qab kev tshuaj xyuas, cov nthwv dej ultrasonic yuav tsum tau siv los ua kev tshuaj xyuas tsis puas tsuaj ntawm sab hauv, yog li cov qhov tsis zoo uas tshwm sim thaum lub sijhawm sib dhos tuaj yeem raug tshem tawm zoo. Tsis tas li ntawd, kev ua cov ncej ntoo khaub lig kuj tseem xav tau. Thaum lub sijhawm teeb tsa cov qauv hlau, koj yuav tsum xaiv cov lus piav qhia tus qauv, kaw lub vas rau kev tswj hwm, thiab tom qab ntawd ua qhov ntsuas ntsug ntawm qhov siab saum toj kawg nkaus. Tom qab ntawd, qhov kev hloov chaw ntawm sab saum toj ntawm kem thiab cov qauv hlau yuav tsum tau ua tiav rau qhov kev hloov pauv super-deflection, thiab tom qab ntawd cov txiaj ntsig super-flat thiab cov txiaj ntsig tshuaj xyuas ntawm kem qis dua raug ua tiav tag nrho. Kev ua tiav ntawm cov taw tuab yuav tsum tau ua tom qab txiav txim siab qhov chaw ntawm kem hlau. Los ntawm kev tshuaj xyuas cov ntaub ntawv ua tiav, qhov ntsug ntawm kem hlau raug kho dua. Tom qab kev teeb tsa tiav lawm, cov ntaub ntawv ntsuas yuav tsum tau tshuaj xyuas thiab cov teeb meem vuam yuav tsum tau tshuaj xyuas. Tsis tas li ntawd, kev kaw ntawm cov ntsiab lus tswj hwm yuav tsum tau tshuaj xyuas dua. Thaum kawg, daim duab qhia ua ntej tswj hwm ntawm kem hlau qis dua yuav tsum tau kos.

DAIM NTAWV THOV

Cov hlau H-beams feem ntau siv rau hauv ntau yam kev tsim kho thiab kev siv engineering vim lawv lub zog, kev hloov pauv tau yooj yim, thiab lub peev xwm thauj khoom. Qee qhov kev siv dav dav ntawm cov hlau H-beams suav nrog:

1. Kev tsim kho vaj tse: H-beams feem ntau siv los ua cov khoom txhawb nqa hauv kev tsim kho vaj tse, suav nrog cov ncej, beams, thiab cov khoom txhawb nqa ru tsev. Lawv muab cov qauv ruaj khov rau cov qauv lag luam thiab cov qauv vaj tse nyob.

2. Kev tsim kho choj: H-beams yog cov khoom tseem ceeb hauv kev tsim choj, qhov chaw uas lawv siv los txhawb qhov hnyav ntawm lub lawj choj thiab pab txhawb kev faib cov khoom thauj thoob plaws hauv qhov qauv.

3. Cov qauv kev lag luam: H-beams ua lub luag haujlwm tseem ceeb hauv kev txhawb nqa cov khoom siv hnyav, tshuab, thiab cov khoom siv hauv cov chaw lag luam xws li cov chaw tsim khoom, cov tsev rau khoom, thiab cov chaw faib khoom.

4. Cov haujlwm tsim kho vaj tse: Cov hlau H-beams siv rau hauv kev tsim kho vaj tse xws li txoj kev loj, txoj kev tsheb ciav hlau, thiab qhov av, qhov twg lawv lub peev xwm thauj khoom yog qhov tseem ceeb rau kev txhawb nqa qhov loj thiab cov khoom hnyav.

5. Cov phab ntsa thiab kev txhim kho: H-beams yog siv ua cov hauv paus tseem ceeb hauv cov phab ntsa thiab cov txheej txheem txhim kho, muab kev ruaj khov ntawm cov qauv thiab kev txhawb nqa rau kev tuav thiab kev ruaj khov ntawm lub ntiaj teb.

6. Kev siv rau kev tsim vaj tsev: Ntxiv rau lawv cov kev siv rau kev tsim kho, H-beams kuj tseem siv rau hauv kev tsim vaj tsev los tsim cov ntsiab lus pom tshwj xeeb, xws li cov beams uas raug nthuav tawm thiab cov yam ntxwv zoo nkauj hauv kev tsim kho niaj hnub.

NTIM THIAB XA KHOOM

Ntim:

Muab cov ntawv sheet piles sib dhos kom ruaj ntseg: Npaj cov ntawv sheet piles kom zooASTM A992 H beamnyob rau hauv ib pawg huv si thiab ruaj khov, xyuas kom meej tias lawv tau teeb tsa kom zoo kom tiv thaiv kev tsis ruaj khov. Siv txoj siv sia lossis txoj siv sia los khi lub pawg kom ruaj khov thiab tiv thaiv kev txav mus los thaum thauj mus los.

Siv cov ntaub ntawv ntim khoom tiv thaiv: Qhwv cov pawg ntawv nrog cov khoom uas tiv taus dej noo, xws li yas lossis ntawv tsis ntub dej, kom tiv thaiv lawv kom tsis txhob raug dej, av noo, thiab lwm yam khoom ib puag ncig. Qhov no yuav pab tiv thaiv xeb thiab xeb.

Kev Xa Khoom:

Xaiv ib txoj kev thauj mus los uas tsim nyog: Nyob ntawm seb muaj pes tsawg thiab qhov hnyav ntawm cov ntawv sheet piles, xaiv txoj kev thauj mus los uas tsim nyog, xws li cov tsheb thauj khoom tiaj tiaj, cov thawv, lossis cov nkoj. Xav txog tej yam xws li qhov deb, lub sijhawm, tus nqi, thiab txhua yam kev cai lij choj rau kev thauj mus los.

Siv cov khoom siv tsa kom tsim nyog: Txhawm rau thauj thiab tshem cov hlau phaj U-puab, siv cov khoom siv tsa kom tsim nyog xws li cranes, forklifts, lossis loaders. Xyuas kom tseeb tias cov khoom siv siv muaj peev xwm txaus los tuav qhov hnyav ntawm cov phaj kom muaj kev nyab xeeb.

Ruaj ntseg cov khoom thauj: Ruaj ntseg cov pawg ntawv uas tau ntim rau ntawm lub tsheb thauj khoom siv txoj siv sia, khi, lossis lwm yam uas tsim nyog los tiv thaiv kev txav, swb, lossis poob thaum lub sijhawm thauj mus los.

LUB TUAM TXHAB LUB ZOG

Ua nyob rau hauv Suav teb, thawj-chav kawm kev pabcuam, txiav-edge zoo, ntiaj teb-nrov npe

1. Cov teebmeem ntawm qhov ntsuas: Peb lub tuam txhab muaj cov khoom siv loj thiab lub Hoobkas hlau loj, ua tiav cov teebmeem ntawm qhov ntsuas hauv kev thauj mus los thiab kev yuav khoom, thiab dhau los ua lub tuam txhab hlau uas koom ua ke kev tsim khoom thiab kev pabcuam

2. Kev sib txawv ntawm cov khoom: Kev sib txawv ntawm cov khoom, txhua yam hlau uas koj xav tau tuaj yeem yuav tau los ntawm peb, feem ntau koom nrog cov qauv hlau, cov hlau rails, cov hlau sheet piles, photovoltaic brackets, channel steel, silicon steel coils thiab lwm yam khoom, uas ua rau nws yooj ywm dua Xaiv hom khoom xav tau kom tau raws li qhov xav tau sib txawv.

3. Kev muab khoom ruaj khov: Muaj cov kab tsim khoom thiab cov saw hlau ruaj khov dua tuaj yeem muab kev muab khoom txhim khu kev qha dua. Qhov no tseem ceeb heev rau cov neeg yuav khoom uas xav tau cov hlau ntau.

4. Kev cuam tshuam ntawm hom lag luam: Muaj kev cuam tshuam ntau dua rau hom lag luam thiab kev ua lag luam loj dua

5. Kev Pabcuam: Ib lub tuam txhab hlau loj uas koom ua ke kev hloov kho, kev thauj mus los thiab kev tsim khoom

6. Kev sib tw nqi: tus nqi tsim nyog

* Xa email mus rau[email tiv thaiv]kom tau txais ib daim ntawv hais txog koj cov haujlwm

Cov Lus Nug Feem Ntau

1. Kuv tuaj yeem tau txais cov lus hais los ntawm koj li cas?

Koj tuaj yeem tawm lus rau peb, thiab peb yuav teb txhua cov lus raws sijhawm.

2. Koj puas yuav xa cov khoom raws sijhawm?

Yog, peb cog lus tias yuav muab cov khoom zoo tshaj plaws thiab xa khoom raws sijhawm. Kev ncaj ncees yog peb lub tuam txhab lub hauv paus.

3. Kuv puas tau txais cov qauv ua ntej kev txiav txim?

Yog, tau kawg. Feem ntau peb cov qauv yog pub dawb, peb tuaj yeem tsim los ntawm koj cov qauv lossis cov duab kos duab.

4. Koj cov nqe lus them nqi yog dab tsi?

Peb lub sijhawm them nyiaj ib txwm yog 30% tso nyiaj, thiab so tawm tsam B / L.

5. Koj puas lees txais kev tshuaj xyuas los ntawm lwm tus?

Yog peb lees txais kiag li.

6. Peb ntseeg koj lub tuam txhab li cas?

Peb tshwj xeeb hauv kev lag luam hlau tau ntau xyoo ua tus neeg muag khoom kub, lub hauv paus chaw nyob hauv xeev Tianjin, txais tos los tshawb xyuas txhua txoj kev, los ntawm txhua txoj kev.