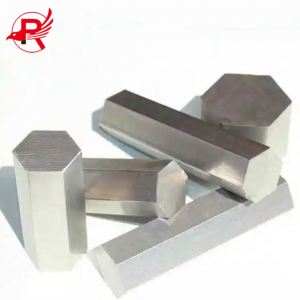

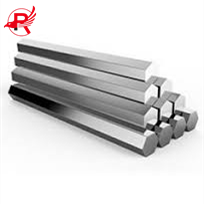

Tuam Tshoj Tus Neeg Muag Khoom Extruded Hexagonal Aluminium Qws Ntev Hexagon Bar 12mm 2016 astm 233

Cov Lus Qhia Txog Khoom

Hexagonal aluminium pas nrig yog cov khoom siv aluminium zoo li hexagonal prism, uas yog cov khoom siv feem ntau siv hauv kev lag luam.

Hexagonal txhuas pas nrig muaj cov yam ntxwv ntawm lub teeb yuag, zoo rigidity, siab zog thiab zoo conductivity, thiab yog dav siv ua cua sov dissipation thiab cov khoom siv hauv cov khoom siv hluav taws xob thiab hluav taws xob.

Vim yog cov yam ntxwv ntawm cov qauv hexagonal, nws yog qhov tsim nyog heev rau kev ua cov khoom thiab pwm ntawm ntau yam duab.

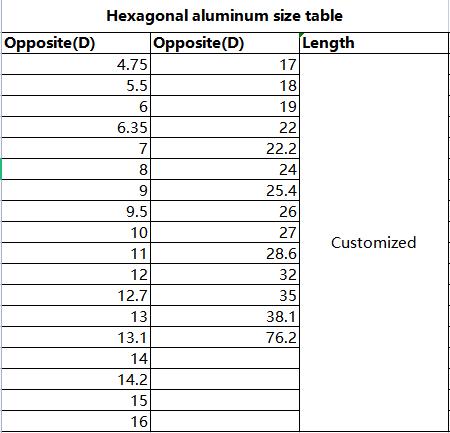

Cov Lus Qhia Tshwj Xeeb

Hauv kev lag luam tsim khoom siv, nws feem ntau yog siv los tsim ntau yam stamping tuag; hauv kev ua khoom siv kho vajtse, nws yog siv los ua ntau yam khoom siv hlau, yeeb nkab thiab ntau yam khoom tshwj xeeb; hauv kev lag luam tsheb, nws tuaj yeem siv rau cov tshuab txias xws li lub cav thaiv thiab lub nruas nres. Lub phaj txhuam rau nws; ntxiv rau, nws kuj tseem siv tau ua cov khoom siv kho xeb rau cov khoom siv tshuaj lom neeg, thiab lwm yam.

Daim Ntawv Thov

1. Haum rau cov khoom siv hluav taws xob thiab hluav taws xob ua cov khoom siv cua sov lossis cov khoom siv, xws li radiators, evaporators, condensers thiab lwm yam khoom siv cua sov.

2. Siv rau lub kaw lus txias ntawm lub cav thaiv hauv kev lag luam tsheb thiab lub phaj txhuam ntawm lub nruas nres; nws kuj tseem siv tau ua cov khoom siv kho xeb hauv cov khoom siv tshuaj lom neeg.

3. Nws tuaj yeem hloov cov khoom tooj liab ua cov khoom siv solder thaum lub sijhawm vuam, xws li: lub taub hau hluav taws xob soldering hlau, lub taub hau phom kub cua sov, hlau solder, pob solder thiab lwm yam.

4. Nws kuj siv tau es tsis txhob siv cov khoom siv quenching rau cov hlau.

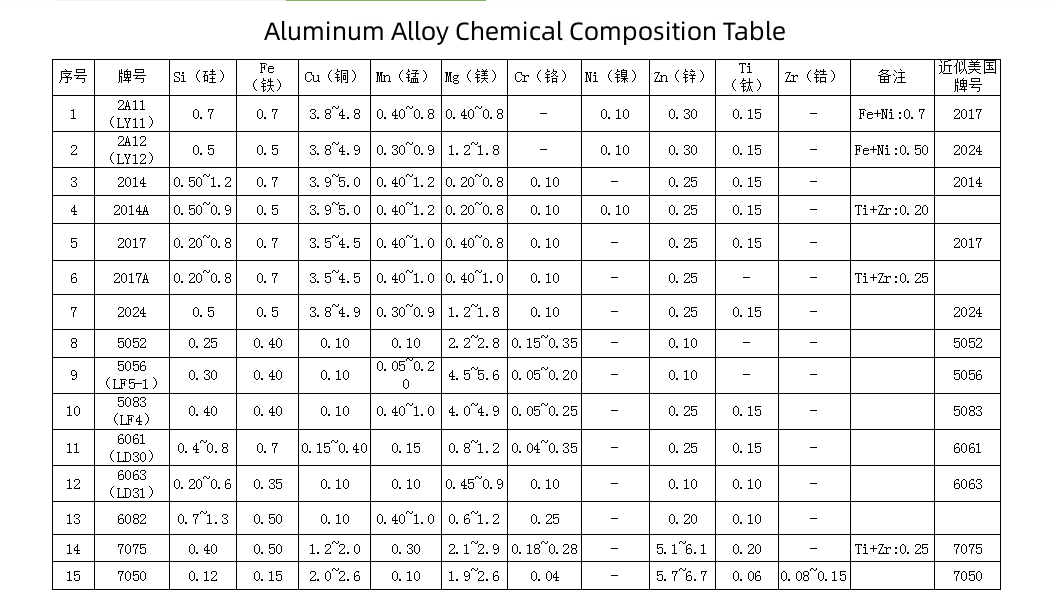

Cov ntaub ntawv txhuas. Cov hauv qab no feem ntau siv 6061 txhuas alloy ua piv txwv los qhia:

6061 Txhuas Alloy

6061 txhuas alloy yog ib qho alloy uas kho tau kub nrog kev ua tau zoo, weldability, machinability, thiab nruab nrab lub zog, thiab tseem tuaj yeem ua haujlwm zoo tom qab annealing.

6061 txhuas alloy tshuaj lom neeg muaj pes tsawg leeg (%):

Cu: 0.15 ~ 0.4 Mn: 0.15 Mg: 0.8 ~ 1.2Zn: 0.25 Cr: 0.04 ~ 0.35 Ti: 0.15 Si: 0.4 ~ 0.8 Fe: 0.7 Al: balance

Daim ntawv thov tseem ceeb: Siv dav hauv ntau yam khoom siv hauv kev lag luam uas xav tau qee lub zog thiab kev tiv thaiv corrosion siab, xws li kev tsim khoom tsheb thauj khoom, tsev siab, nkoj, trams, thiab tsheb ciav hlau. 6061 txhuas alloy cov yam ntxwv:

Lub zog tensile kawg ntawm 6061 txhuas alloy yog 124MPa, lub zog tensile yog 5.2MPa, tus nqi elongation yog 25.0%, lub modulus ntawm elasticity yog 68.9 GPa, thiab lub zog khoov kawg yog 28MPa.

6061 feem ntau siv rau hauv cov khoom siv aerospace, cov tsheb thauj khoom, cov qauv pej thuam, cov kav dej, cov nkoj, cov dav hlau, aerospace, kev tiv thaiv thiab lwm yam kev siv architectural uas xav tau lub zog, weldability thiab corrosion resistance.

6061 txhuas alloy muaj cov txiaj ntsig zoo li nram no: 1. Cov hlau kho cua sov muaj zog heev. 2. Cov khoom siv kho tshuab zoo. 3. Siv tau zoo. 4. Yooj yim rau kev ua, tiv taus kev hnav zoo. 5. Tiv taus kev xeb thiab tiv taus oxidation zoo.

6061 txhuas alloy feem ntau siv rau hauv cov khoom siv aerospace, tsheb thauj khoom, tsev siab, kav dej, nkoj, dav hlau, kev tsav dav hlau, kev tiv thaiv thiab lwm yam kev siv architectural uas xav tau lub zog, weldability thiab corrosion tsis kam. Xws li: aircraft qhov chaw, iav thiab shafts, fuse qhov chaw, twj paj nruag shafts thiab iav, kev nyab xeeb qhov chaw dhia valve, turbines, yuam sij, thiab lwm yam.

Nws yog ib qho hlau A-Mg-Si uas muaj zog nruab nrab, zoo plasticity thiab zoo heev corrosion tsis kam. Tshwj xeeb, tsis muaj kev ntxhov siab corrosion tawg, nws weldability zoo heev, corrosion tsis kam thiab txias ua haujlwm tau zoo, nws yog ib hom kev siv dav. Zoo heev cog lus alloy. Nws tuaj yeem anodized thiab xim, thiab kuj tuaj yeem pleev xim nrog enamel, uas yog tsim rau cov khoom siv kho kom zoo nkauj. Nws muaj me ntsis Cu, yog li nws lub zog siab dua li ntawm 6063, tab sis nws rhiab heev rau quenching.

3, Cov Yam Ntxwv thiab Kev Txhim Kho ntawm Cov Seem Rail:

Nws kuj tseem siab dua 6063. Kev tua cua tsis tuaj yeem ua tiav tom qab extrusion, thiab nws yuav tsum tau rov ua dua thiab quenched kom tau txais lub zog siab dua.

Cov khoom siv tseem ceeb ntawm 6061 Taiwan kub yog magnesium thiab silicon, thiab tsim Mg2Si theem. Yog tias nws muaj qee qhov manganese thiab chromium, nws tuaj yeem tshem tawm cov teebmeem tsis zoo ntawm hlau; qee zaum ntxiv me ntsis tooj liab lossis zinc los txhim kho qhov nyuaj ntawm cov hlau.

Lub zog yam tsis txo qis nws txoj kev tiv thaiv corrosion; muaj me ntsis tooj liab hauv cov khoom siv conductive los cuam tshuam cov teebmeem tsis zoo ntawm titanium thiab hlau ntawm conductivity; txhuas lossis titanium tuaj yeem ua kom cov noob zoo thiab tswj cov qauv recrystallization;

Yuav kom txhim kho kev siv tshuab tau zoo, koj tuaj yeem ntxiv cov hlau lead thiab bismuth. Cov kua khov ntawm Mg2Si hauv txhuas ua rau cov hlau muaj lub luag haujlwm ntawm kev laus dag.

6061-T651 yog cov hlau tseem ceeb ntawm 6061 hlau. Nws yog cov khoom siv aluminium alloy zoo uas tsim los ntawm kev kho cua sov thiab cov txheej txheem ncab ua ntej. Txawm hais tias nws lub zog tsis tuaj yeem piv rau 2XXX series lossis 7XXX series, nws cov hlau magnesium thiab silicon yog qhov tshwj xeeb.

Nws muaj ntau yam khoom, kev ua haujlwm zoo heev, cov yam ntxwv vuam zoo heev thiab cov khoom siv electroplating, kev tiv thaiv corrosion zoo, siab toughness thiab tsis muaj deformation tom qab ua tiav, cov khoom siv ntom tsis muaj qhov tsis xws luag thiab yooj yim rau polish, yooj yim rau thov xim zaj duab xis, zoo heev oxidation nyhuv thiab lwm yam zoo heev.

4, Daim ntawv qhia txog kev tsim khoom ntawm txoj kev tsheb ciav hlau:

Yaj → casting → sawing rods → homogenizing aluminium rods → txias, ntxuav rods → aluminium rods rau hauv lub tsev rau khoom.

Cov Lus Nug Feem Ntau

1. Kuv tuaj yeem tau txais cov lus hais los ntawm koj li cas?

Koj tuaj yeem tawm lus rau peb, thiab peb yuav teb txhua cov lus raws sijhawm.

2. Koj puas yuav xa cov khoom raws sijhawm?

Yog, peb cog lus tias yuav muab cov khoom zoo tshaj plaws thiab xa khoom raws sijhawm. Kev ncaj ncees yog peb lub tuam txhab lub hauv paus.

3. Kuv puas tau txais cov qauv ua ntej kev txiav txim?

Yog, tau kawg. Feem ntau peb cov qauv yog pub dawb, peb tuaj yeem tsim los ntawm koj cov qauv lossis cov duab kos duab.

4. Koj cov nqe lus them nqi yog dab tsi?

Peb lub sijhawm them nyiaj ib txwm yog 30% tso nyiaj, thiab so tawm tsam B / L. EXW, FOB, CFR, CIF.

5. Koj puas lees txais kev tshuaj xyuas los ntawm lwm tus?

Yog peb lees txais kiag li.

6. Peb ntseeg koj lub tuam txhab li cas?

Peb tshwj xeeb hauv kev lag luam hlau tau ntau xyoo ua tus neeg muag khoom kub, lub hauv paus chaw nyob hauv xeev Tianjin, txais tos los tshawb xyuas txhua txoj kev, los ntawm txhua txoj kev.