Nyob rau hauv lub ntuj ci ntsa iab ntawm cov khoom siv hlau,Tooj Liab Coiltau siv dav hauv ntau qhov chaw nrog lawv qhov kev zoo nkauj tshwj xeeb, los ntawm kev kho kom zoo nkauj thaum ub mus rau kev tsim khoom lag luam tshiab. Niaj hnub no, cia peb los saib tob txog cov kauj tooj liab thiab qhia lawv daim ntaub thaiv zais cia.

1. Coil Tooj Liab yog dab tsi?

Tooj liab, tseem hu ua tooj liab liab, yog lub npe tom qab cov xim av oxide zaj duab xis tsim tom qab oxidation ntawm nws qhov chaw. Lub ntsiab tivthaiv yog tooj liab, nrog cov ntsiab lus ntawm ntau dua 99.5% thiab ob peb yam tsis huv. Cov kauj tooj liab yog ua los ntawm tooj liab ua cov khoom siv raw thiab ua tiav los ntawm ntau cov txheej txheem. Vim tias tooj liab muaj kev ua hluav taws xob zoo, kev ua kom sov thiab kev ua haujlwm yooj yim, cov kauj tooj liab tau txais cov khoom zoo no thiab tau dhau los ua "tus hlub" ntawm ntau lub lag luam.

Cov yam ntxwv ntawm cov kauj tooj liab

1. Kev ua hluav taws xob zoo heev

Qhov hluav taws xob ntawm cov kauj tooj liab yog qhov thib ob tom qab nyiaj, qeb thib ob ntawm txhua yam hlau. Qhov no ua rau nws yog cov khoom siv zoo tshaj plaws rau kev tsim cov hlau thiab cable. Hauv kev xa hluav taws xob, cov cables ua los ntawm cov kauj tooj liab tuaj yeem txo qhov tsis kam, txo qhov poob ntawm lub zog hluav taws xob thaum xa hluav taws xob, thiab xyuas kom ruaj khov thiab ua haujlwm tau zoo.

2. Kev ua kom sov zoo

Cov kauj tooj liab muaj cov thermal conductivity zoo heev thiab tuaj yeem nqus thiab hloov pauv cua sov sai sai. Hauv kev tsim cov khoom siv xws li cov cua sov sib pauv thiab radiators, cov kauj tooj liab yog cov khoom siv nyiam. Piv txwv li, lub radiator ntawm lub cav tsheb yog ua los ntawmtooj liab kauj, uas tuaj yeem tshem tawm cov cua sov uas lub cav tsim tawm sai sai, xyuas kom lub cav ua haujlwm ntawm qhov kub thiab txias tsim nyog, thiab ua kom nws lub neej ua haujlwm ntev dua.

3. Kev tiv thaiv xeb zoo heev

Ib daim zaj duab xis oxide ntom ntom tuaj yeem tsim rau ntawm qhov chaw ntawm tooj liab. Daim zaj duab xis oxide no zoo li "daim zaj duab xis tiv thaiv" los tiv thaiv tooj liab kom tsis txhob oxidation thiab xeb ntxiv. Hauv qhov chaw muaj pa roj av noo lossis xeb, cov kav dej, cov thawv, thiab lwm yam ua los ntawm cov kauj tooj liab tseem tuaj yeem ua haujlwm zoo thiab yuav tsis yooj yim xeb thiab puas tsuaj.

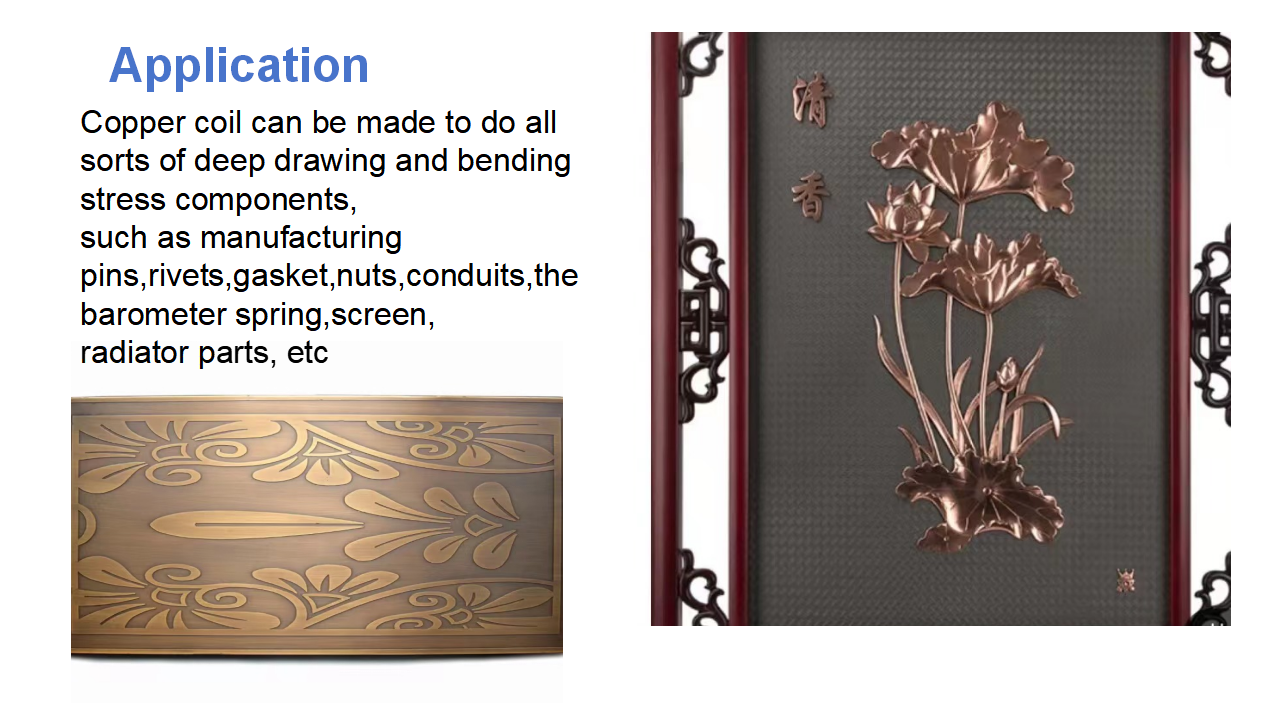

4. Kev ua haujlwm zoo heev

Tooj liab muaj qhov zoo ductility thiab plasticity thiab yooj yim rau kev ua. Cov kauj tooj liab tuaj yeem ua rau ntau qhov chaw ntawm cov duab nyuaj los ntawm ntau txoj kev ua xws li stamping, ncab, thiab khoov kom tau raws li ntau yam kev xav tau ntawm ntau yam kev lag luam sib txawv.

Cov teb thov ntawm Cov Coils Tooj Liab

1. Kev lag luam fais fab

Hauv kev lag luam fais fab, cov kauj tooj liab siv dav hauv kev tsim cov khoom siv xws li cov xov hlau thiab cov cables, transformers, thiab cov txee hloov pauv. Cov xov tooj liab zoo tuaj yeem ua kom muaj kev ruaj khov thiab kev ntseeg siab ntawm kev xa hluav taws xob, thiab cov xov tooj liab hauv transformers tuaj yeem txhim kho kev ua haujlwm zoo thiab kev ua tau zoo ntawm transformers.

2. Kev lag luam tsim kho

Hauv kev tsim kho, cov kauj tooj liab feem ntau siv rau hauv kev tsim cov ru tsev, phab ntsa, cov kab dai kom zoo nkauj, thiab lwm yam. Cov xim tshwj xeeb thiab ci ntsa iab ntawm tooj liab tuaj yeem ntxiv ib puag ncig kos duab tshwj xeeb rau lub tsev thiab txhim kho qhov zoo nkauj thiab tus nqi ntawm lub tsev. Tsis tas li ntawd, cov kav dej ua los ntawm cov kauj tooj liab yog cov uas tsis xeb thiab muaj lub neej ua haujlwm ntev, thiab siv dav hauv kev tsim cov dej thiab cov dej ntws.

3. Kev lag luam hluav taws xob

Cov kauj tooj liab siv dav hauv kev lag luam hluav taws xob thiab yog cov khoom siv tseem ceeb rau kev tsim cov ntawv luam tawm Circuit Board thiab cov khoom siv hluav taws xob. Qhov ua tau zoo ntawm hluav taws xob thiab thermal conductivity ntawm tooj liab tuaj yeem ua tau raws li qhov xav tau ntawm cov khoom siv hluav taws xob rau cov ntaub ntawv ua tau zoo thiab ua kom cov khoom siv hluav taws xob ua haujlwm ruaj khov.

4. Kev lag luam tsim khoom siv tshuab

Hauv kev tsim cov tshuab, cov kauj tooj liab feem ntau siv los tsim ntau yam khoom, xws li cov kabmob, cov iav, cov ntsaws ruaj ruaj, thiab lwm yam. Qhov kev tiv thaiv kev hnav thiab cov khoom siv lubricating ntawm tooj liab tuaj yeem txo qhov kev sib txhuam thiab kev hnav ntawm cov khoom thiab txhim kho lub neej kev pabcuam thiab kev ua haujlwm zoo ntawm cov khoom siv tshuab.

Cov kauj tooj liab ua lub luag haujlwm tseem ceeb hauv ntau yam lag luam vim lawv cov hluav taws xob zoo heev, thermal conductivity, corrosion resistance thiab processing performance. Nrog rau kev nce qib ntawm kev tshawb fawb thiab thev naus laus zis, cov chaw siv cov kauj tooj liab yuav txuas ntxiv nthuav dav. Kuv ntseeg tias yav tom ntej, cov kauj tooj liab yuav txuas ntxiv pab txhawb rau kev txhim kho ntawm tib neeg lub zej zog thiab sau ib tshooj tshiab zoo kawg nkaus.

Yog tias koj xav tau cov kauj tooj liab, thov tawm lus hauv thaj chaw tawm tswv yim los qhia koj cov kev xav thiab kev paub!

Chaw Nyob

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, Suav

Xov tooj

+86 13652091506

Lub sijhawm tshaj tawm: Lub Peb Hlis-24-2025